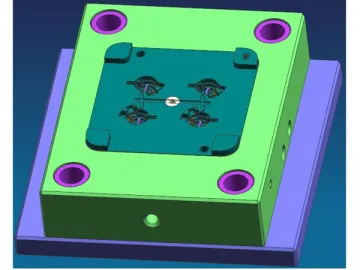

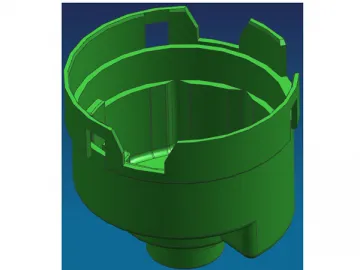

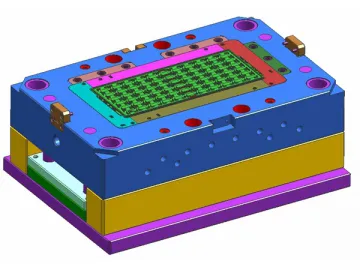

Plastic Carrier Mold

Plastic Carrier Mold

The plastic carrier mold uses polyphthalamide (PPA) in theinjection molding. This material is a semi-crystalline thermoplastic polyamide,or high-temperature resistance aromatic nylon. Under long term workingcondition, it comes with 180 cent degree heat resistance. While in shortworking temperature, it enjoys a property of a heat resistance of 290 centdegree. Hence, the molded plastic carrier still has high performanceunder high temperature.

Detailed Information of Plastic Carrier

| Project Name | Carrier |

| Number of Parts | 4 parts in 1 tooling |

| Material | PPA 30%gf FR (Grade HTR 52 G30NH BK 337) |

| Product Size | Ф 20*15 |

| Exported Country/Customer | India |

Detailed Information of Plastic Carrier Mold

| Cavity No. | 1*4 | Plastic | PPA 30%gf | Tonnage of Moulding Machine | 100T |

| Core Cavity Material | 1.2083 | Mold Life Warranty | 500K | Mould Type | 3 plate |

| Mould Size | 400*450*300 | Mold Base | LKM S50C | Mold Features | NA |

| Mould Weight | 400 kg | Runner System | Cold runner | Gate Type | Lateral gate |

Our plastic carrier mold takes good advantages of the excellent thermal,electrical, physical and chemical properties of PPA material. Combined withother excellent characteristics, such as dimensional accuracy and stability,high rigidity, high strength, high cost performance, low water absorption rate,etc., the mold product is widely applied in electronic and electrical,mechanical engineering, automotive and other fields.

Links:https://www.globefindpro.com/products/88746.html

-

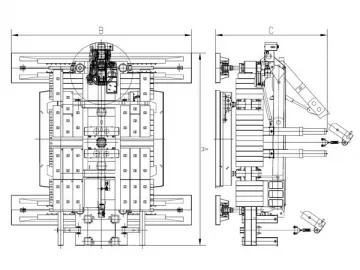

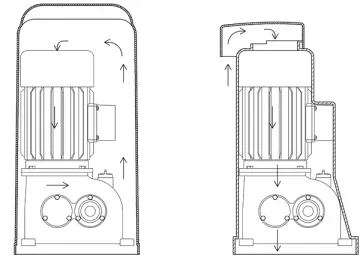

Silent Hydraulic Pile Driving Machine

Silent Hydraulic Pile Driving Machine

-

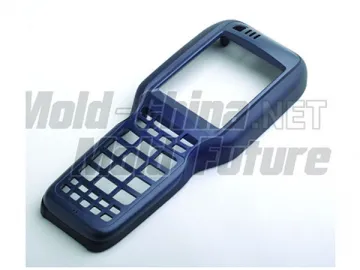

Handhold POS Mold

Handhold POS Mold

-

Hydraulic Vibratory Hammer

Hydraulic Vibratory Hammer

-

Plastic Case Mold

Plastic Case Mold

-

POM Injection Mold

POM Injection Mold

-

IC Tray Mold

IC Tray Mold

-

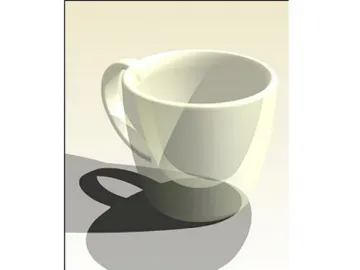

Plastic Cup Mold

Plastic Cup Mold

-

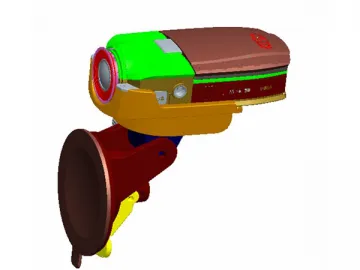

Car Video Recorder Mold

Car Video Recorder Mold

-

Paddlewheel Aerator Spare Parts

Paddlewheel Aerator Spare Parts

-

Fiber Cement Wall Corner (Pre-Manufactured Mitered Corners)

Fiber Cement Wall Corner (Pre-Manufactured Mitered Corners)

-

Splash Aerator

Splash Aerator

-

Diesel Drive Multi Impeller Paddlewheel Aerator

Diesel Drive Multi Impeller Paddlewheel Aerator