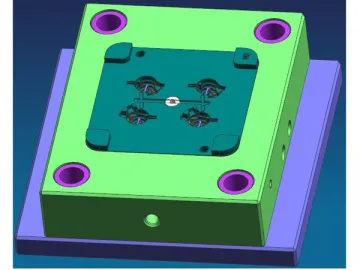

Plastic Case Mold

Plastic Case Mold

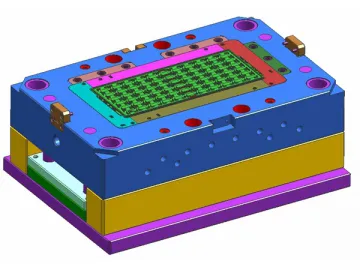

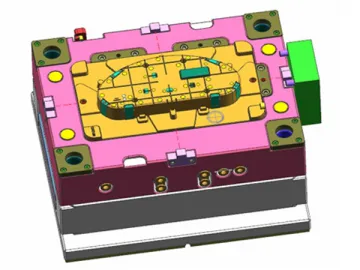

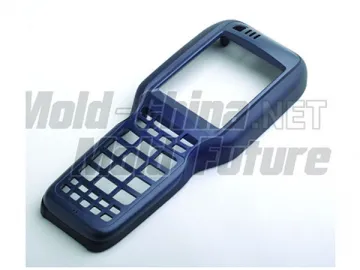

This series of plasticcase mold can create the POM parts with a dimension of 38.5mm × 34.8mm. Withtwo cavities, it can produce two parts at the same time. Adopting 1.2344 Germansteel for the cavity and S50C steel for the base, the mold is not likely to bedamaged. It also comes with hot runner, three plates and pin-point gate. Theseall enable the mold to produce high quality plastic parts.

Detailed Plastic Case Information

| Project Name | Case |

| Number of Parts | 2 parts in 1 tooling |

| Material | POM |

| Product Size | Ф 38.5*34.8 |

| Exported Country/Customer | India |

Tooling Information

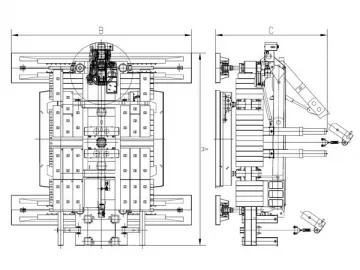

| Cavity No. | 1*2 | Plastic | POM | Moulding Machine | 100 T Sumitomo |

| Core Cavity Material | 1.2344 German Steel | Mold Life Warranty | 500K | Mould Type | 3 plate |

| Mould Size | 500*500 | Mold Base | S50C | Mold Features | HASCO std |

| Mould Weight | 500kg | Runner | Hot Runner (Mold Master) | Gate Type | Pin-point gate |

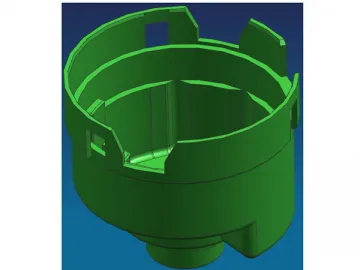

The plastic case mold is available with the material of polyoxymethylene (POM), which is also known asSuper-Steel and Steel-Match and is one of the top 5 engineering plastics (PA,PC, POM, PET or PBT, PPO). Due to this high performance engineering plastic,the molded plastic case is widely used in aerospace and aviation, electronicsand electrics, automobiles, mechanics, instruments, pipe fittings and lightindustry.

The available material POM has the properties of good strength, creepresistance, fatigue resistance, dimensional stability, formability, and highgross. This ensures high performance of our plastic case. It is also durablewhen in contact with inorganic pharmaceuticals and oil, and comes with wearresistance and long term sliding. Hence, the material can be made into manykinds of components, such as mechanical components, home appliances parts, autoparts, and cosmetics box.

Links:https://www.globefindpro.com/products/88753.html