POM Injection Mold

POM Injection Mold

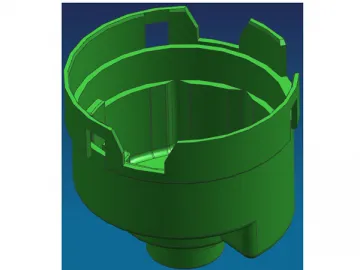

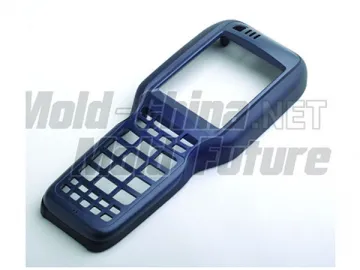

Our POM injection mold takes advantage of polyoxymethylene (POM, acetal homopolymer,polyacetal)material, which has excellent machining characteristics just like the metal, as well as the property of dimensionalstability. With good thermal stability, the material also allows for steamsterilization. Typically, this engineering resin is applied in theprototyping and manufacture of printer part, gear, hinge,and other mechanical parts.

ProductInformation

| Project Name | Printer Part;Gear;Hinge,etc. |

| Number of Parts | 8 parts |

| Material | POM |

| Product Size | 10-100mm per side |

| Exported Country/Customer | Spain |

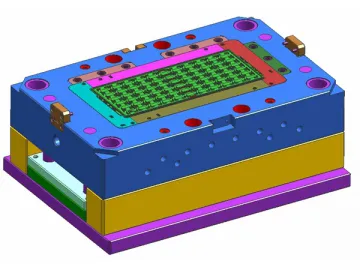

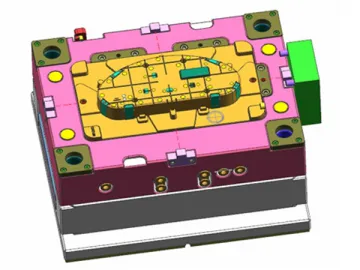

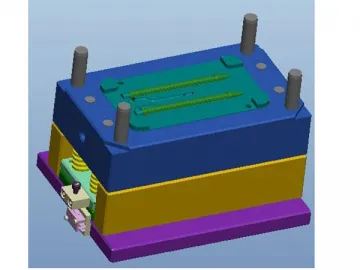

Tooling Information

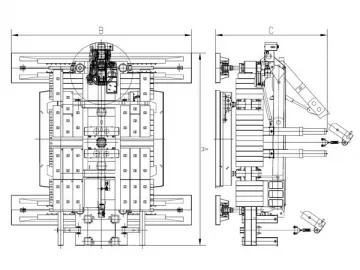

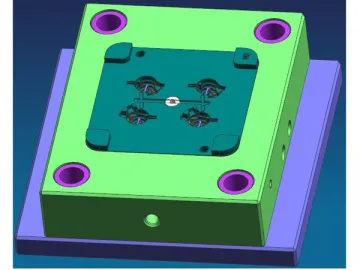

| Cavity No. | 1* 2 | Plastic | POM | Tonnage of Moulding Machine | 150T |

| Core Cavity Material | S136 (48-52HRC) | Mold Life Warranty | 300K | Mould Type | 2 plate |

| Mould Size | 550x500x400 | Mold Base | LKM S50C | Mold Features | 4 slider No lifter |

| Mould Weight | 750.284 kg | Runner System | Could Runner | Gate Type | No |

This series of POMinjection mold is used for producing printer parts, gears, hinges and otherparts made of POM. The size ofthese parts is controlled with the range between 10mm and 100mm, the shape canbe made into various types, and the precision is relatively high. The moldcomes with the size of 550mm × 500mm × 400mm and the weight of 750kg. It adoptsLKM S50C steel as the base material, which is very solid. In order to improveproduction efficiency, it uses dual-cavity design for processing two productsonce. In addition, the cavity is made from S136 steel, whichwill not affect the quality of manufacturing parts after long time working.What’s more, the POM injection mold can produce as much as 300K items and enjoyslong service life.

Links:https://www.globefindpro.com/products/88755.html