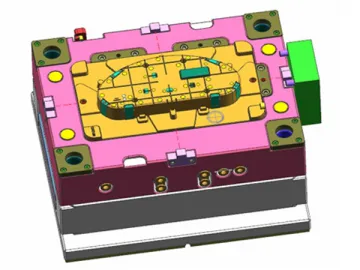

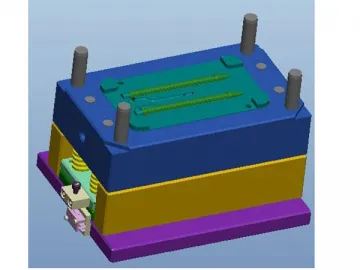

IC Tray Mold

IC Tray Mold

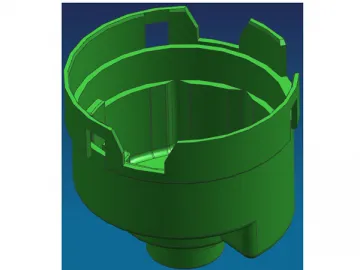

Our IC tray mold can produce IC salver used for the package of flash chips. The molded producthas good anti-static performanceand can resist heat at 150 degrees. Combined with unique PPE resin and the highquality tooling as well, the IC tray can be processed with high plainness. Withyears of production experience, we can provide customers with such tooling andproduct.

The adopted plastic material PPE (Polyphenylene) for the IC tray mold is also referredas to PPO (Polyphenylene Oxide). Characterized by outstanding mechanical, thermal, and electricalproperties, this strong engineering plastic also features low moistureabsorption and low thermal expansion. What’s more, working and molding of thismaterial is rather easy. Due to theseadvantages, PPE plastic is widely used in the injection molding and many otherfields.

Product Information

| Project Name | Flash Chip Tray / IC Tray |

| Number of Parts | 1part |

| Material | PPE |

| Product Size | 322*135*13.2mm |

| Country/Customer | Korea, Japan, Taiwan, China |

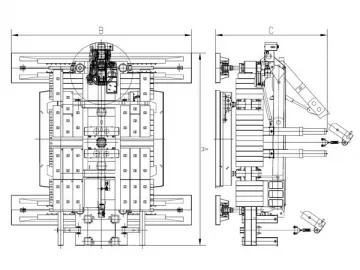

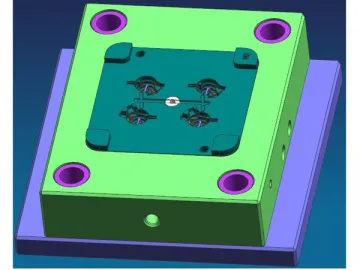

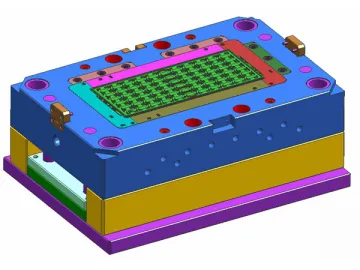

Mold Information

| Cavity No. | 1*1 | Plastic | PPE | Moulding Machine | 200T |

| Core Cavity Material | 1.2083 German Steel | Mold Life Warranty | 500K | Mould Type | 2 plate |

| Mould Size | 500*400*400 | Mold Base | LKM S50C | Mold Features | NA |

| Mould Weight | 600 kg | Runner System | YUDO Hot runner | Gate Type | Needle Valve gate, Open gate |

Links:https://www.globefindpro.com/products/88760.html