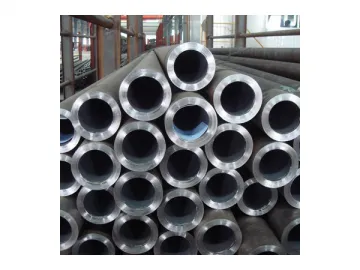

Galvanized Steel Tube

Galvanized Steel Tube

By taking hot galvanizing mode to make the surface galvanized with zinc coating, the galvanized steel tube, also called as galvanized iron pipe, can be protected from corrosion. Through hot dip galvanization, the base body of the product reacts with the zinc in molten bath. Thus, the formed zinc coating is uniform, compacted and has high adhesion, which allows for long service lifetime of the product. We can provide the product with the outside diameter ranging from 21.3mm to 219mm, the wall thickness of 0.4mm to 13mm and the length of 3m to 12m. But the length can also be customized according to customers’ requirements.

Technical Specifications

1. Welding Mode: High Frequency Welding

2. Weight of the Zinc Coating: The zinc coating weight for per square meter according to customers’ requirements.

3. Outside Diameter: 21.3-219 mm

4. Wall Thickness: 0.4-13 mm

5. Length: It’s generally from 3m to 12m. But we have the service of customization.

6. Material: Q195, Q215, Q235, Q345, GR.A, GR.B, API J55, API K55, 10#, 20#, etc

7. Standards: ASTM-A53, BS1378-1985, GB/T3091-2001, GB/T3087 or in accordance with the demands of customers

8. Packaging: We often package the products in bundle, in unfastening state or seaworthy packing. But customers can have their own requirements.

Application

The galvanized steel tube is often employed as anti corrosion pipe. So it’s commonly used for outdoor construction such as fence and handrail building. It can also be used as indoor pipeline. For its advantage of high resistance to corrosion, the product has been an ideal choice for protecting the goods and materials which would be exposed to the elements on a regular basis from damage.

Notes

1. There are often threads on either end of the product. So a small amount of adhesive is needed on the threads to reinforce the connection of two steel pipes.

2. If there is no thread on the end of the product, the fitting can be welded to the product. But the operator should get aware of that there would generate zinc fume during the welding process. The zinc fume is harmful to people’s health.

Links:https://www.globefindpro.com/products/88779.html