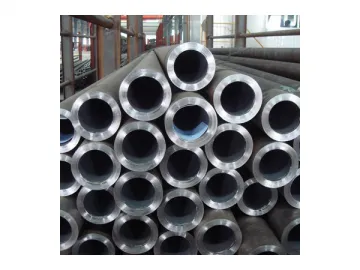

Spiral Steel Pipe

Spiral Steel Pipe

The spiral steel pipe of our company has large size range with the outside diameter from 159mm to 3020mm and the wall thickness from 4mm to 25mm. Its length generally ranges from 6m to 12m. But the product can be customized in the aspects of outside diameter, wall thickness, length, grade and steel strength according to customers’ requirements.

Features

1. Welded with spiral welding seam, the spiral steel pipe can be manufactured by strip steel with any diameters.

2. It has higher strength and rigidity than longitudinal welded steel tube. The spiral welding mode can reduce the defects during the welding process, which can lead to the better crack resistance property.

3. The superior structural strength allows for fewer connections and hangers during the transportation work.

4. The long lifespan reduces the installation operation intervals, which lower the cost effectively and assures the related project working reliably for a long time.

Technical Specifications

Outside Diameter | 159-3020mm in Theory | ||

Thickness | 4-25mm in Theory | ||

Length | We usually provide the product with the length from 6m to 12m. Theoretically, the length can be almost endless. But there is a limit considering the actual transportation work. | ||

Standard | SY/T5037, SY/T5040, GB/T9711, API5L, EN10208, ASTM A252, JISA5525 | ||

Material | Chinese Grade | ||

Foreign Grade | ASTM | Grade A, Grade B, X42, X46, X52, X56, X60, X65, X70 | |

EN | S185, S235JR, S235JO, E335, S355JR, S355JO, L245, L290, L320, L360, L390, L415, L450 | ||

Ends | The product can be processed with plain end or beveled end which can be protected by plastic cap or steel ring according to customers’ requirements. We can also weld the flange on the end of the pipe. | ||

Surface | Bared or Painted with Oil, Bitumen or PE with 1to 3 layers | ||

Inspection | Chemical Composition, Mechanical Properties Testing, Hydrostatic Test, Dimensional and Visual Inspection and Nondestructive Inspection | ||

Technique | Hot Rolled and SSAW or DSAW | ||

Application

Designed for the application with requirements of high velocity and high pressure, the spiral steel pipe has been applied in many areas such as air conditioning system, above and below ground distribution systems with high or medium pressure, agricultural irrigation and urban construction to achieve ventilation, dust removal, grain handling, carbon monoxide exhaust and dual wall pipe for sound and thermal isolation. It can also be used for transporting water, sewage, stream and combustible fluid such as petroleum and gas.

Links:https://www.globefindpro.com/products/88794.html