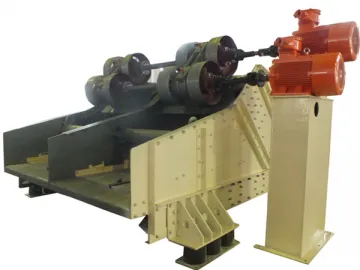

Belt Conveyor

Belt Conveyor

The belt conveyor is widely used to convey scatteredmaterial or bulk material in mining, metallurgy, and coal industry. It hasfeatures of high conveying capacity, simple structure, easymaintenance and parts standardization. The belt conveyoris applicable at a temperature range from -20 oCto 40 oCwith a feedstock temperature below 50 oC. Accordingto the conveying process requirements, theproduct can be used independently or combined with other transportationequipment to form horizontal or incline transportation system.

Specifications

| Model | Belt length(m)/power(kw) | Speed (m/s) | Production capacity(t/h) | ||

| I (L/KW) | II (L/KW) | III (L/KW) | |||

| B400 | ≤ 12/1.5 | 12-20/2.2-4 | 20-25/3.5-7.5 | 1.3-1.6 | 40-80 |

| B500 | ≤ 12/3 | 12-20/4-5.5 | 20-30/5.5-7.5 | 1.3-1.6 | 80-190 |

| B650 | ≤ 12/4 | 12-20/5.5 | 20-30/7.5-11 | 1.3-1.6 | 130-320 |

| B800 | ≤ 6/4 | 6-15/5.5 | 15-30/7.5-15 | 1.3-1.6 | 280-550 |

| B1000 | ≤ 10/5.5 | 10-20/7.5-11 | 20-40/11-12 | 1.3-2 | 440-850 |

| B1200 | ≤ 10/7.5 | 10-20/11 | 20-40/15-30 | 1.3-2 | 660-1200 |

Note: 1. Theconveying capacity is calculated according to the density of loose rubble whichis estimated at 1.6t/m3 in the Table.

2. The angle of the belt conveyor after installation is ≤18º (here theconveying capacity is estimated based on 0º angle).

3. Customization according to your need is available.

Links:https://www.globefindpro.com/products/88868.html