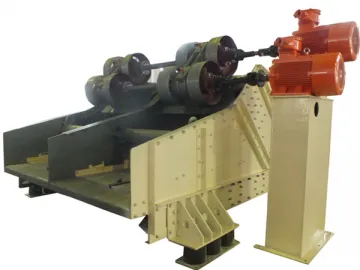

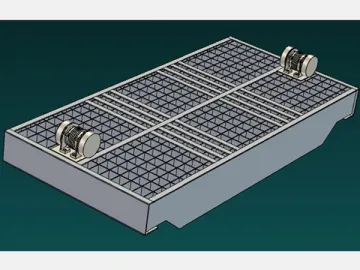

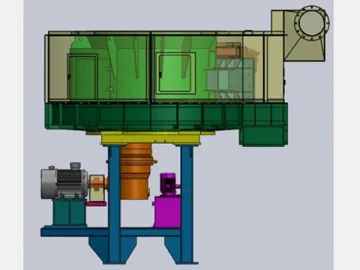

Disc Feeder

DiscFeeder

The disc feeder is applicable for continuous feeding of non-viscouspowder or small particle. It is transmitted by a reducer and slewing ring whichmakes the disc move circularly. The feeding is available by the aiding ofsleeve, blade and valve.The hardened tooth reducer, adjustable feeding valve and large diameter slewingring are adopted. The disc feeder has an independent lubrication system and ashcleaning device in the lower side. There is no need to clear storage formaintenance. In sum, it is an ideal feeder showing properties of long lifespanand low operation cost.

Specifications

| Model | Disc diameter(mm) | Max. feeding size(mm) | Production capacity(m3/h) | Motor | Power (kw) | Rotation speed (rpm) |

| WYPG-1000 | 1000 | 40 | 14 | Y112M-6 | 2.2 | 7.5 |

| WYPG-1500 | 1500 | 55 | 25 | Y132M2-6 | 5.5 | 7.5 |

| WYPG-1700 | 1700 | 60 | 42 | Y160L-6 | 11 | 6.3 |

| WYPG-2000 | 2000 | 80 | 30-130 | YVP180L-4 | 22 | 2-8 |

| WYPG-2500 | 2500 | 80 | 15-150 | YVP180L-4 | 22 | 0.6-6 |

| WYPG-3000 | 3000 | 80 | 75-180 | YVP200L-4 | 30 | 1.3-3.1 |

Features

1. The disc feeder adopts wear resistant lining plate.

2. The screen pore is unlikely to be blocked.

3. Automatic clearing feedstock is available.

Links:https://www.globefindpro.com/products/88869.html