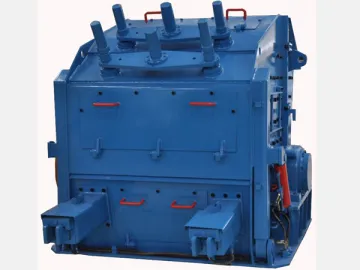

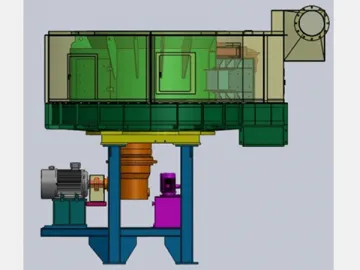

Impact Crusher

ImpactCrusher

The impact crusher is commonly used for crushing feedstock with adiameter smaller than 400 mmand compressive strength less than 300 MPa in thesecondary crushing process. The special design including multi-cavity type,high chromium blow bar and impact plate is especially applicable for the brokenrock treatment. Alow and large inlet facilitates the arrangement of production line and allowsmore feedstock size choices. The final products are uniform cubic particles. Theirsizes are adjustable. The usage of wearable material for blow bar, impact plateand scaleboard further makes the impact crusher moredurable.

Specifications

| Model | Size(mm) | Inlet size(mm) | Max. feeding size(mm) | Production capacity(t/h) | Power(kW) | Weight(t) |

| PF-0807 | ø850×700 | 400×730 | 300 | 15-30 | 30-45 | 8.1 |

| PF-1007 | ø1000×700 | 400×730 | 300 | 30-50 | 37-55 | 9.5 |

| PF-1 1 10 | ø1 1 00×1050 | 400×1080 | 350 | 50- 9 0 | 55- 110 | 12. 3 |

| PF-1210 | ø1250×1050 | 400×1080 | 350 | 70-120 | 110-132 | 14.9 |

| PF-1214 | ø1250×1400 | 400×1430 | 350 | 130-180 | 132-160 | 18.6 |

| PF-1310 | ø1300×1050 | 490×1170 | 400 | 80-140 | 110-160 | 16.2 |

| PF-1315 | ø1320×1500 | 860×1520 | 500 | 160-250 | 180-260 | 19.3 |

| PF-1415 | ø1450×1500 | 1145×1520 | 950 | 220-450 | 220-315 | 27 |

| PF-1520 | ø1520×2000 | 830×2050 | 700 | 300-550 | 315-440 | 38.5 |

| PF-1818 | ø1800×1800 | 1600×1850 | 1000 | 600-850 | 650-900 | 75 |

Links:https://www.globefindpro.com/products/88874.html

-

Wheel Mounted Mobile Crushing and Screening Plant

Wheel Mounted Mobile Crushing and Screening Plant

-

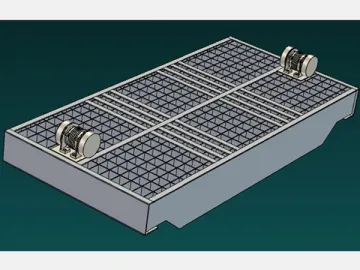

Vibrating Board

Vibrating Board

-

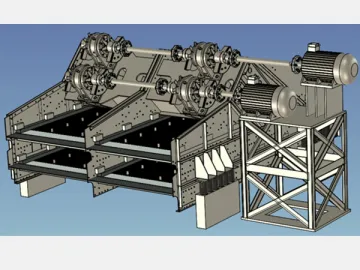

Large Scale Desliming Screen

Large Scale Desliming Screen

-

Polyurethane Comb Screen Plate

Polyurethane Comb Screen Plate

-

Polyurethane Rectangular Screen Plate

Polyurethane Rectangular Screen Plate

-

Electromagnetic Feeder

Electromagnetic Feeder

-

Cardan Shaft

Cardan Shaft

-

Biaxial Circular Vibrating Screen

Biaxial Circular Vibrating Screen

-

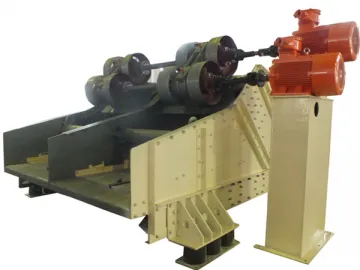

Dual Channel Linear Screen

Dual Channel Linear Screen

-

Disc Feeder

Disc Feeder

-

Belt Conveyor

Belt Conveyor

-

Large Amplitude Screen

Large Amplitude Screen