HO5SJ-K Fiberglass Braided Heat Resistant Silicone Rubber Insulation Wire

HO5SJ-K Fiberglass Braided Heat Resistant Silicone Rubber InsulationWire

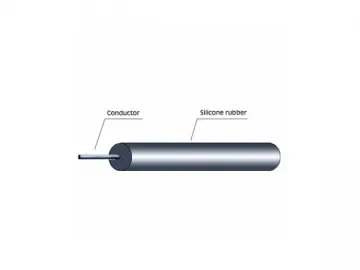

Braided wireconsists of, from inside to outside, conductor, insulator, shield and jacket.Our HO5SJ-K fiberglass braided heat resistant silicone rubber insulation wirehas bare brass or tin coated copper wire conductor. Its insulator is made ofsilicone rubber which has terrific electrical insulation and anti ageingability as well as heat and coldness resistance. This fiberglass braidedinsulation wire has medium fiberglass braided layer. Its rated working voltageis 300V or 500V. It can be used under the environment temperature from -60℃ to 180℃.The external jacket of this insulation wire is silicone resin coating. Thischemical coat features great anti thermal oxidation and electrical insulation.The tensile strength of our product before ageing treatment is 5.0N/mm² and theelongation is 150%. After being treated under the environment temperature of 200℃,three degrees plus and minus, its tensile strength becomes 4.0 N/mm² and itselongation becomes 120%。

Wire Lettering: H05SJ-K ( 1×0.5mm²~1×16mm²) WU XI HUA CHENG CABLE CO.,LTD. LICENCE NO:124381

| Items | Technical datas | Applied standard | ||

| Outer appearance | Smooth, even, without loose | DIN VDE 0282-601 DIN VDE 0282-1:1999.01 DIN VDE 0282-2:1999.01 | ||

| Spark test | AC7KV/ 0.15 S | |||

| Vol. test | 2 KV/15 min | |||

| mechanical properties of insulation material | Before aging | Tensile strength | ≥5.0N/mm² | |

| elongation at break | ≥150% | |||

| After aging | Tensile strength | ≥4.0N/mm² | ||

| (200±3℃×240h) | elongation at break | ≥120% | ||

| Poisonous substance control | Comply with ROHS rule | EU—2002/95/EC | ||

| H05SJ-K | |||||||||

| section | conductor | insulation | braid thick | wire OD | conductor resistance | ||||

| structure | diameter | nominal thick | min. thick | diameter | nominal | allowance | 20℃ | ||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | mm | Ω/KM |

| 0.5 | 28/0.15 16/0.20 20/0.18 | 0.95 | 0.60 | 0.44 | 2.15 | 0.20 | 2.55 | ±0.15 | 40.1 |

| 0.75 | 24/0.20 30/0.18 | 1.15 | 0.60 | 0.44 | 2.35 | 0.20 | 2.75 | ±0.15 | 26.7 |

| 1.0 | 32/0.20 | 1.34 | 0.60 | 0.44 | 2.55 | 0.20 | 2.95 | 0.20 | 20.0 |

| -0.15 | |||||||||

| 1.5 | 30/0.25 | 1.60 | 0.70 | 0.53 | 3.00 | 0.20 | 3.40 | 0.20 | 13.7 |

| -0.15 | |||||||||

| 2.5 | 49/0.25 | 2.00 | 0.80 | 0.62 | 3.60 | 0.25 | 4.10 | 0.30 | 8.21 |

| -0.15 | |||||||||

| 4.0 | 56/0.30 | 2.70 | 0.80 | 0.62 | 4.30 | 0.25 | 4.80 | 0.30 | 5.09 |

| -0.15 | |||||||||

| 6.0 | 84/0.30 | 3.30 | 0.80 | 0.62 | 4.90 | 0.25 | 5.40 | 0.30 | 3.39 |

| -0.15 | |||||||||

| 10 | 84/0.40 | 4.60 | 1.00 | 0.80 | 6.60 | 0.25 | 7.10 | 0.30 | 1.95 |

| -0.15 | |||||||||

| 16 | 126/0.40 | 5.80 | 1.00 | 0.80 | 7.80 | 0.25 | 8.30 | 0.30 | 1.24 |

| -0.15 | |||||||||

Links:https://www.globefindpro.com/products/89150.html

-

SIHF/SIHE Heat Resistant Silicone Cable

SIHF/SIHE Heat Resistant Silicone Cable

-

4×0.22mm2 FG FEP Silicone Rubber Sheath Heat Resistant Cable

4×0.22mm2 FG FEP Silicone Rubber Sheath Heat Resistant Cable

-

2×0.22mm2 FG FEP Silicone Rubber Sheath Heat Resistant Cable

2×0.22mm2 FG FEP Silicone Rubber Sheath Heat Resistant Cable

-

AWM 3469 XLPE Insulated Wire

AWM 3469 XLPE Insulated Wire

-

GTO Silicone Rubber High Voltage Wire

GTO Silicone Rubber High Voltage Wire

-

4×0.23mm2 FG FEP Silicone Rubber Sheath Heat Resistant Cable

4×0.23mm2 FG FEP Silicone Rubber Sheath Heat Resistant Cable

-

IEC 60245 Heat Resistant Silicone Rubber Insulation Wire

IEC 60245 Heat Resistant Silicone Rubber Insulation Wire

-

N2GFAF/N2GFA Silicone Rubber Insulation Wire

N2GFAF/N2GFA Silicone Rubber Insulation Wire

-

HO5S-K Heat Resistant Silicone Rubber Insulation Wire

HO5S-K Heat Resistant Silicone Rubber Insulation Wire

-

AWM 1056 PVC Insulated Wire

AWM 1056 PVC Insulated Wire

-

AWM 1060 PVC Insulated Wire

AWM 1060 PVC Insulated Wire

-

N2GFAF/SIF Silicone Rubber Insulation Braided Wire

N2GFAF/SIF Silicone Rubber Insulation Braided Wire