CV1000 Vertical Machining Center

CV1000 vertical machining center adopts the result design with high rigidity. The rapid displacement of X and Y axis are both 36 m/min while Z axis is 24 m/min. The spindle has a maximum speed of 12,000 rpm. The tool change time is only 1.5 s. The product adopts a new generation of control system with novel appearance and the design of no back type.

:CV1000-8-1CV1000-8-2()

Thanks to the adoption of the oil-water separation design, CV1000 vertical machine center can effectively separate the oil from cutting liquid and prevent the cutting fluid from mixing and deterioration which can affect the processing quality

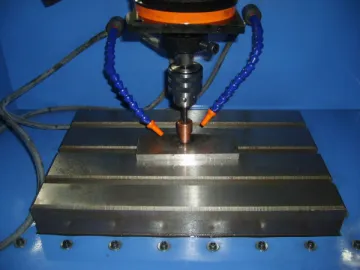

Spindle and Spindle Cooling System

:CV1000-8-3CV1000-8-4()

1. Thanks to the unique and economic design of the cooling system of head, it can take heat away generated by the operational spindle with a high speed and avoid heat displacement problem of spindle head.

2. The cooling system of CV800 vertical machine center can achieve an excellent cooling effect without the help of filter or hydraulic oil.

3. The product can lower the heat generated by the high-speed operational spindle, thereby ensuring the precision of the spindle and extending its service life.

4. In the dry cutting condition, the system also has a crossing design which still can retain the cooling efficiency.

:CV1000-8-5()

Humanized Operation Interface of CV1000 Vertical Machine Center

:CV1000-13-1()

1. The rotated operation panel can meet safety standards and can be easily operated.

2. Fault warning signal is displayed on the screen, so it is easy to remove.

3. It is convenient to operate due to the design of suspended and rotatable boom and touch buttons, graphics and text displays.

4. Thanks to the circular English display interface, we can easily understand.

5. The operation interface provides important keys with protective cover on the panel, thus avoiding the wrong actions after confirmation.

Technical Parameters of CV1000 Vertical Machine Center

Model/Specification CV1000A  | ||

Travel | ||

X travel | mm (inch) | 1020 (40.2) |

Y travel | mm (inch) | 560 (22.0) |

Z travel | mm (inch) | 600 (23.6) |

nose to table | mm (inch) | 135-735 (5.3-28.9) |

Spindle | ||

Spindle rotation speed | rpm | 8000 |

Automatic Tool Changer | ||

Tool number | pc | 20 |

Max. tool diameter | mm (inch) | 100 (3.9) |

Max. tool length | mm (inch) | 305 (12.0) |

Max. tool weight | kg (lb) | 7 (15.4) |

ATC type | Drum type | |

Tool shank | #40 | |

Motor | ||

Spindle motor (cont / 30min. rated) | kw (hp) | 7.5/11 (10/14.7) |

X/Y/Z servo motor | kw (hp) | 2 / 2 / 2 (2.7 / 2.7 / 2.7) |

Table | ||

Table size | mm (inch) | 1000x560 (39.3x22.0) |

Max. load capacity | kg (lb) | 750 (1650) |

T-slot (number x width x distance) | mm (inch) | 5x18x100 (5x0.7x3.9) |

Rapid Feed | ||

X-axis | M/min | 24 (78.7) |

Y-axis | M/min | 24 (78.7) |

Z-axis | M/min | 18 (59.1) |

Cutting Feedrate | mm/min | 1-10000 (0.04-394) |

Controller | ||

Mitsubishi | M70 | |

Miscellaneous | ||

Machine weight | kg (lb) | 7000 (15400) |

Power requirement | KVA | 25 |

Coolant capacity | L | 290 |

Air source | kg/cm2 (psi) | 6 (85) |

Model/Specification CV1000B | ||

Travel | ||

X travel | mm (inch) | 1020 (40.2) |

Y travel | mm (inch) | 560 (22.0) |

Z travel | mm (inch) | 600 (23.6) |

nose to table | mm (inch) | 135-735 (5.3-28.9) |

Spindle | ||

Spindle speed | rpm | 8000 |

Automatic Tool Changer | ||

Tool number | no . | 20 |

Max. tool diameter | mm (inch) | 100 (3.9) |

Max. tool length | mm (inch) | 305 (12.0) |

Max. tool weight | kg (lb) | 7 (15.4) |

ATC type | Arm type | |

Tool shank | #40 | |

Motor | ||

Spindle motor (cont / 30min. rated) | kw (hp) | 11/15 (15/20) |

X/Y/Z servo motor | kw (hp) | 2 / 2 / 2 (2.7 / 2.7 / 2.7) |

Table | ||

Table size | mm (inch) | 1000x560 (39.3x22.0) |

Max. load capacity | kg (lb) | 750 (1650) |

T-slot (number x width x distance) | mm (inch) | 5x18x100 (5x0.7x3.9) |

Rapid Feed | ||

X-axis | M/min | 24 (78.7) |

Y-axis | M/min | 24 (78.7) |

Z-axis | M/min | 18 (59.1) |

Cutting Feedrate | mm/min | 1-10000 (0.04-394) |

Controller | ||

Mitsubishi | M70 | |

Others | ||

Machine weight | kg (lb) | 7000 (15400) |

Power requirement | KVA | 25 |

Coolant capacity | L | 290 |

Air source | kg/cm2 (psi) | 6 (85) |

Links:https://www.globefindpro.com/products/89332.html

-

2 Piece Flanged End Ball Valve

2 Piece Flanged End Ball Valve

-

Reducing Tee

Reducing Tee

-

DK7732 CNC Wire Cut EDM Machine

DK7732 CNC Wire Cut EDM Machine

-

Pipe Elbow 45°

Pipe Elbow 45°

-

DK7740 CNC Wire Cut EDM Machine

DK7740 CNC Wire Cut EDM Machine

-

Stainless Steel Reducer

Stainless Steel Reducer

-

ZNC325 Sinker EDM Machine

ZNC325 Sinker EDM Machine

-

Hex Head Plug

Hex Head Plug

-

Socket Weld End Union

Socket Weld End Union

-

3 Piece Ball Valve With Mounting Pad (Threaded Ends)

3 Piece Ball Valve With Mounting Pad (Threaded Ends)

-

Hex Equal Nipple

Hex Equal Nipple

-

Stainless Steel Plate Flange

Stainless Steel Plate Flange