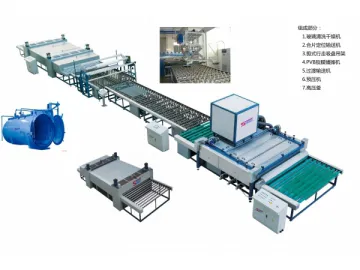

Crystal Glass Mosaic Tile Production Line

Crystal Glass Mosaic Tile Production Line

The crystal glass mosaic tile production line comprises of glass washer,multi-blade glass cutter, silk screen printer, drying line, mosaic paddlemachine, chromatographic proofing furnace, and roller electrothermal (gas) tunnelcalcining kiln.

The crystal glass mosaictile production line is mainly used to make plate glass with 4mm to 10mm thickness into all kinds of crystal glass mosaictile. The monthly output can be 5,000 to 20,000 square meters. Thisnew-generation environmental friendly product has the advantages of highefficiency, low power consumption, and high accuracy in temperaturecontrolling. The production cycle is 50 days.

Technical Specification

| Furnace Length | 28-36m, segmental |

| Cross Section of Furnace Mouth | 0.8-1.3m (two boards or three boards) |

| Maximum Service Temperature | 1,000℃ (adjustable) |

| Electric Power | 120-250 (kW/380V) |

| Heating Method | Electric |

| Electric Heating Element | Electric furnace heating wire, silicon carbide rod |

| Temperature Controlling Method | PID intelligent digital display temperature controlling, SCR module controlling, linear scale output, manual and automatic adjustment, ±1℃ accuracy. (Computer remote controlling designable.) |

| Temperature Controlling Point | 4-6 points |

| Rollers | φ40mm alumina ceramics rollers |

| Driving Method | Helical gears |

| Rollers Speed Controlling | 2 grades frequency conversion speed regulation |

| Cooling Method | Natural cooling or forced cooling |

Models of Crystal Glass Mosaic TileProduction Line

| Model | Power (kW) | Temp. (℃) | Controlling Method | Rollers Speed (min/mm) | Cross Section of Furnace (mm) | Length of Furnace (m) |

| WRBT-9 | 90 | 1,000 | PID intelligent controlling | 150-600 | B500×H80 | 25 |

| WRBT-16 | 160 | 1,000 | PID intelligent controlling | 150-600 | B800×H100 | 28 |

| WRBT-18 | 180 | 1,000 | PID intelligent controlling | 150-600 | B1000×H100 | 28 |

Electrothermal Kiln

The kiln adopts segmental steel structure with each section 2m long. The maximum service temperature is 1,000℃.It comes with ceramic rollers and helical gears driving method. Frequencyconversion speed regulation and PID intelligent multi-points temperaturecontrol are also available.

Specification and Output

| Specification of Mosaic Tile | Daily Output 24h | Rollers Furnace | Total Power Consumption | Power Consumption Per Square Meter of Mosaic Tile |

| 4mm -10mm | 150-100 ㎡ | L24m×B1.8m×H1.5m | 210Kw/380V | 12-15Kw/ ㎡ |

| 4mm -10mm | 300-240 ㎡ | L28.5m×B2.0m×H1.5m | 300Kw/380v | 10-12 Kw / ㎡ |

| 4mm -10mm | 450-360 ㎡ | L36m×B2.5m×H1.5m | 400Kw/380v | 10-12 Kw / ㎡ |

| 4mm -10mm | 600-500 ㎡ | L36m×B3.0m×H1.5m | 500Kw/380v | 10-12 Kw / ㎡ |

Natural Gas Kiln

This kiln also adopts segmental steel structure. Each section is 2m long. It has the same ceramic rollers andhelical gears driving method. In addition to frequency conversion speedregulation, it has several functions such as automatic ignition and automaticconstant temperature controlling. The maximum service temperature is 1000℃.

Specification and Output

| Specification of Mosaic Tile | Daily Output 24h | Rollers Furnace | Total Power Consumption | Power Consumption Per Square Meter of Mosaic Tile | |

| 4mm -10mm | 150-100 ㎡ | L30m×B2.0m×H1.8m | 50Kw/380V | 25-40m³/ ㎡ | |

| 4mm -10mm | 300-240 ㎡ | L35m×B2.5m×H1.8m | 60Kw/380v | 30-50 Kw / ㎡ | |

| 4mm -10mm | 450-360 ㎡ | L40m×B3.0m×H1.8m | 60Kw/380v | 40-65m³/ ㎡ | |

| 4mm -10mm | 600-500 ㎡ | L45m×B3.5m×H1.8m | 60Kw/380v | 60-85m³/ ㎡ | |

Links:https://www.globefindpro.com/products/89430.html

-

Box Glass Decorating Lehr

Box Glass Decorating Lehr

-

Optical Glass Lens Production Line

Optical Glass Lens Production Line

-

Crucible Fuel Gas Glass Melting Furnace

Crucible Fuel Gas Glass Melting Furnace

-

Experimental Electrothermal Glass Melting Furnace

Experimental Electrothermal Glass Melting Furnace

-

1400℃ Fuel Gas Furnace

1400℃ Fuel Gas Furnace

-

Industrial Radiation Shield

Industrial Radiation Shield

-

Glass Bead Production Line

Glass Bead Production Line

-

Sandwich Glass Production Line

Sandwich Glass Production Line

-

Crucible Electrothermal Glass Melting Furnace

Crucible Electrothermal Glass Melting Furnace

-

Ceramic Tube, Ceramic Bead, Ceramic Terminal Block

Ceramic Tube, Ceramic Bead, Ceramic Terminal Block

-

Blind Flange

Blind Flange

-

Stainless Steel Expansion Bellow

Stainless Steel Expansion Bellow