Horizontal Bead Mill

HorizontalBead Mill

Horizontal bead mill consists of rack, chamber, grinding stick, feed pump,circulation pump of seal liquid, sealed tank, pressure gauge, thermometer andcontrol box.

The equipment operation issimple because no installation is needed. Before use, 1.0-1.2mm diameter zirconia beads should be added into the chamber ofthe bead mill and directions of motor rotation and arrow should be checkedbefore running to make sure they are consistent with each other. Bearing shouldbe lubricated regularly and beads should be filtered and replaced on a regularbasis. A word of warning, empty machine running is strictly prohibited.

There are three different types of horizontal bead mill, including pigment mill, colorant mill,pesticide mill, industrial coating mill, and offset ink mill and they havetheir own applications, specifications and features.

Horizontal Bead Mill (Pigment / Colorant Mill)

: 10-1()

The horizontal bead millcan be extensively used in paint, pigment, dye, colorant, ink, pesticide, pharmaceutical, paper and other industries.According to its applications, it is also called a pigment mill or colorantmill.

Firstly, equipped with double mechanical seal and material compatible coolantmakes the bead mill more reliable and durable and pollution of grindingmaterial is reduced dramatically. Secondly, tungsten carbide mixer and importedzirconia beads can be used forgrinding and dispersion of a wide viscosity range of materials and structuralperformance of loaded beads can be adjusted to meet different requirements. Inaddition to that, tungsten carbide cylinder rod pins are mounted on the rotorand chamber to strengthen the impact and shearing function thus dispersedgrinding is improved. In respect of fineness, the horizontal bead mill is perfectly tailored for the materials whichrequire high viscosity and fineness and generally fineness can reach to 5microns by dispersed grinding of solid particles.

Detailed Specifications

| Model | KWS-15 | KWS-25 |

| Main Motor Power(KW) | 11 | 22 |

| Main Shaft Speed(rpm) | 1200 | 900 |

| Working Volume of Chamber(L) | 15 | 25 |

| Production Range(L/h) | 40-400 | 60-600 |

| Cooling Water Consumption(m3/h) | 1.2 | 1.5 |

| Compressed Air Pressure(MPa) | 0.6-0.8 | 0.6-0.8 |

| Grinding Medium | Zarconia Beads | Zarconia Beads |

Applications

| Paint and Varnish | Pigment |

| Water-Based Paint | Dye |

| Concentrated Color Paste | Pesticide |

| Magnetic Recording Material | Auto Paint |

| Special Paint | Paper |

| Printing Ink | Pharmaceutical |

Horizontal Bead Mill (Pesticide /Industrial Coating Mill)

: 10-2()

Thehorizontal bead mill is applicable to industries like offset printing ink,fluorescent ink, concentrated colorant, UV ink, printing ink, especially forgrinding of pesticide suspension and industrial paint. So, it can also becalled a pesticide mill or industrial coating mill according to itsapplications.

The pesticide and industrial coating mill is equipped with double mechanicalseal and material compatible coolant, so it features higher reliability anddurability, and pollution of grinding material is reduced dramatically. Withthe function of slot and multi-contour, dispersion disk enables strong impactand friction among the sphere of the grinding media thus high-efficiencygrinding and dispersion of the material is guaranteed. In respect of fineness,the horizontal bead mill is perfectly tailored for the materials which requirehigh viscosity and fineness and generally fineness can reach to 10 microns bydispersed grinding of solid particles in a short period of time. The simpleoperation, outstanding reliability and high production efficiency make industrialcoating and pesticide mill the best choice for customers.

Detailed Specifications

| Model | JWS-5 | JWS-15 | JWS-30 | JWS-50 |

| Motor Power(KW) | 5.5 | 11 | 22 | 37 |

| Main Shaft Speed(rpm) | 1800 | 980 | 900 | 750 |

| Working Volume of Chamber(L) | 5 | 15 | 30 | 50 |

| Production Range(L/h) | 120-480 | 120-600 | 120-720 | 120-720 |

| Grinding Medium | Zirconia bead | |||

Horizontal Bead Mill (Offset Ink Mill)

: 10-3()

This type ofhorizontal bead mill can be comprehensively used in paint, pigment, dye,colorant, ink, pesticide, pharmaceutical, paper and other industries,especially for grinding of offset ink. Due to its main application range, it isalso called an offset ink mill.

The horizontal bead mill isequipped with wear-resistant cylinder cone chamber, tungsten carbide rod pinmixer and bead loading adjustment device, which make this machine manufacturedhighly applicable for grinding of media and high viscosity materials. Inrespect of fineness, the offset inkmill is perfectly tailored for the materials which require highviscosity and fineness and generally fineness can reach to 5 microns bydispersed grinding of solid particles.

Detailed Specifications

| Main Motor Power(KW) | 22 |

| Chamber Volume(L) | 6 |

| Production Range (L/h) | 30-350 |

| Cooling Water Consumption(m3/h) | 1.3 |

| Compressed Air Pressure(MPa ) | 0.6-0.8 |

| Grinding Medium | Zarconia bead |

Links:https://www.globefindpro.com/products/89745.html

-

Solid Liquid Mixture Extruder

Solid Liquid Mixture Extruder

-

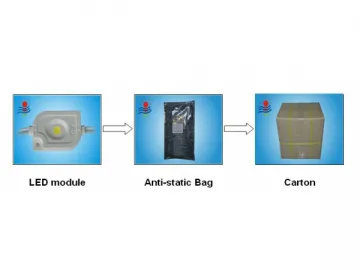

5050 Waterproof LED Display Module

5050 Waterproof LED Display Module

-

Bag Filter

Bag Filter

-

High Speed Disperser (Liquid & Solid Dispersion)

High Speed Disperser (Liquid & Solid Dispersion)

-

Horizontal Ball Mill (Attritor)

Horizontal Ball Mill (Attritor)

-

5050 Waterproof LED Display Module

5050 Waterproof LED Display Module

-

Lab High Speed Disperser & Bead Mill

Lab High Speed Disperser & Bead Mill

-

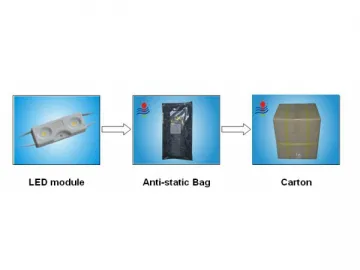

5730 Waterproof LED Display Module

5730 Waterproof LED Display Module

-

High Speed Disperser (Paint and Coatings Disperser)

High Speed Disperser (Paint and Coatings Disperser)

-

3528 Waterproof LED Display Module

3528 Waterproof LED Display Module

-

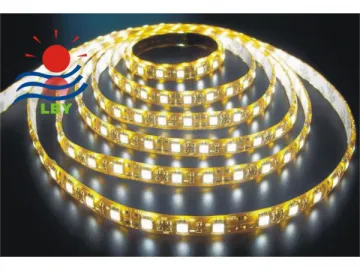

SMD 5050 Flexible Strip Light

SMD 5050 Flexible Strip Light

-

High Power LED Display Module

High Power LED Display Module