Virgin PET Film

VirginPET Film

Our company providescustomers with a variety of quality virgin PET films. The A-PET(Amorphous-polyethylene terephthalate) film is anamorphous thermoplastic material composed of carbon hydrogen and oxygenelements. This product is environmentally friendly because it will not producetoxic gases in the process of combustion. Our A-PET film is now widely used inapplications including vacuum forming, food packaging, boxes folding, UV offsetprinting, screen printing, stationery, card cases, collection cards, etc. In addition, we can alsosupply G-PET or G/A/G sheet that can be used in ultrasonic sealing, highfrequency sealing and solvent sealing.

Roll Type

| Item | |||||

| Thickness | Width | Core | Min. | Max. | |

| 0.12 mm ~0.16 mm | 100 mm ~135 mm | 50 mm ~67 mm | 3” , 6” | 250 mm | 800 mm |

| 0.17 mm ~0.19 mm | 100 mm ~145 mm | 50 mm ~72 mm | 3” , 6” | 250 mm | 800 mm |

| 0.20 mm ~0.59 mm | 100 mm ~150 mm | 50 mm ~75 mm | 3” , 6” | 250 mm | 800 mm |

| 0.60 mm ~1.30 mm | 100 mm ~152 mm | 50 mm ~76 mm | 6” | 250 mm | 800 mm |

Sheet Type

| Item | Length | Height/Pallet | ||

| Thickness | Width | |||

| 0.2 mm ~0.6 mm | 85 mm ~146 mm | 50 mm ~73 mm | 40 mm ~120 mm | 40 mm ~80 mm |

A-PET Sheet TechnicalParameters

| Properties | Unit | SA Coated | Print level | Antiblock silicon free | Antistatic silicon free | ESD | Conductive |

| Thickness of film tested | mm | 0.13~1.8 | 0.3~0.6 | 0.13~1.8 | 0.25~1.8 | 0.25~1.8 | 0.25~1.8 |

| Width | mm | 350~1400 | 350~1300 | 600~1400 | 600~1400 | 600~1400 | 600~1400 |

| Diameter | 300~800 | 300~800 | 300~800 | 300~800 | 300~800 | 300~800 | |

| Density | g/cm3 | 1.35 | 1.35 | 1.35 | 1.35 | 1.35 | 1.35 |

| Haze Total light transmittance | % % | 0.7(0.3 mm) 92 (0.3 mm) | 0.7(0.3 mm) 91(0.3 mm) | 0.8(0.3 mm) 91(0.3 mm) | 2.0(0.3 mm) 89(0.3 mm) | 2.0(0.3 mm) 89(0.3 mm) | 2.0(0.3 mm) 89(0.3 mm) |

| Tensile strength @yield MD TD | Kg/c ㎡ Kg/c ㎡ | >450 >450 | >450 >450 | >450 >450 | >450 >450 | >450 >450 | >450 >450 |

| Tensile modulus of AutYoung MD TD | Kg/c ㎡ Kg/c ㎡ | >17000 >17000 | >17000 >17000 | >17000 >17000 | >17000 >17000 | >17000 >17000 | >17000 >17000 |

| Elongation @yield MD TD | % % | >3.0 >3.0 | >3.0 >3.0 | >3.0 >3.0 | >3.0 >3.0 | >3.0 >3.0 | >3.0 >3.0 |

| Dart impact | g/mm | >1600 | >1600 | >1600 | >1600 | >1600 | >1600 |

| Thermal glass transition temperature Melting temperature Recrystallization temperature | ( ℃ ) ( ℃ ) ( ℃ ) ( ℃ ) | 68 125 248 181 | 68 125 248 181 | 68 125 248 181 | 68 125 248 181 | 68 125 248 181 | 68 125 248 181 |

| Anti-static film surface resistivity (Humidity 50% ± 2%) (25℃ ) | ) | 109-1011 | 106-109 | <106 | |||

| Dyne-Surface |

Our virgin PET film offers good gas and water barrier properties, hightoughness and stiffness as well as great impact resistance. Additional benefitsof our product include high clarity and gloss, no toxicity, no odor, strongchemical resistance, oil resistance, and gamma radiation resistance. All ofthis combines to make our transparent PET film a product of choice forcustomers around the world.

Links:https://www.globefindpro.com/products/89849.html

-

LT-7700 Amateur Portable Radio Transceiver

LT-7700 Amateur Portable Radio Transceiver

-

LT-3670 Amateur Portable Radio Transceiver

LT-3670 Amateur Portable Radio Transceiver

-

Laminated PVC/PE Film

Laminated PVC/PE Film

-

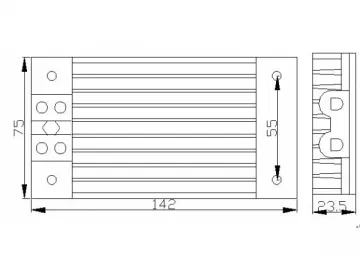

DJR100W Industrial Heat Sink

DJR100W Industrial Heat Sink

-

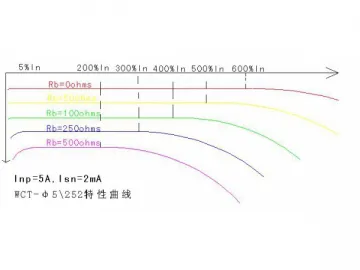

Φ5 Mini Wire Lead Current Transformer

Φ5 Mini Wire Lead Current Transformer

-

DJR300B Industrial Heat Sink

DJR300B Industrial Heat Sink

-

Offset Printing

Offset Printing

-

LT-8500 Amateur Portable Radio Transceiver

LT-8500 Amateur Portable Radio Transceiver

-

IC-V8 Amateur Portable Radio Transceiver

IC-V8 Amateur Portable Radio Transceiver

-

LT-5500 Professional Portable Radio Transceiver

LT-5500 Professional Portable Radio Transceiver

-

Silk Screen Printing

Silk Screen Printing

-

Recycled PET Film

Recycled PET Film