Transparent Rigid PVC Film

TransparentRigid PVC Film

Serial Number:FPVCR3-120302

Our transparent rigid PVCfilm offers many great features, such as light weight, high clarity and gloss,great impact resistance, good thermal formability, etc. In addition, it issuitable for die cutting, thermal deep drawing, laminating and printing. ThePVC film has found a wide variety of applications, including thermoformingpackaging, folding box, skin and blister packaging, electronic devices packing,food packaging, stationery, metallizing,and more.

To ensure the quality of our products, we conduct strict quality inspections onour transparent rigid PVC films before delivery. Our monthly production of 3000tons enables us to quickly meet customers’ any sized orders.

Specifications

| Thickness | 0.05-1.0 mm |

| Width(max) | 2100 mm |

| Packaging | in rolls or in sheets |

| In rolls | 50 kg or 100 kg per package, outer packaging: kraft paper |

| Roll core | 3" or 6" |

| In sheets | 100-1000 sheets per package, PE wrapped |

Rigid PVC Technical Parameters

| Property | Test Method | Unit | Vacuum Forming | Food Packaging | Fold Molding | |||||||

| VB | VD | VG | VS | FB | FC | FF | FD | BB | BF | |||

| Chroma | Transparent | / | ||||||||||

| Opaque | / | / | / | |||||||||

| Specific Gravity | ASTM-D 792-66 | ± 3 % | 1.32 | 1.35 | 1.35 | 1.36 | 1.35 | 1.35 | 1.35 | 1.35 | 1.35 | 1.35 |

| Tensile Strength | ASTM-D 638/882 | kg/c ㎡ (min.) | 450 | 450 | 450 | 460 | 450 | 450 | 450 | 450 | 450 | 450 |

| Tensile Elongation | ASTM-D 638/882 | % (min.) | 80-120 | 80-150 | 80-150 | 80-120 | 80-150 | 100-150 | 100-150 | 80-150 | 80-150 | 80-150 |

| Vicat Temperature | ASTM-D 1525-76 | ℃ (min.) | 80 | 83 | 83 | 83 | 83 | 83 | 83 | 83 | 83 | 83 |

| ASTM-D 1637 | ℃ (min) | 65 | 68 | 68 | 68 | 68 | 68 | 65 | 68 | 68 | 68 | |

| Transparency | ASTM-D 71003.61 | % (min.) | 90.5 | 85 | 85 | 85 | 88 | 30 | 40 | 85 | 88 | 88 |

| Haze | ASTM-D 71003.61 | % (max.) | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | / | / | 3.0 | 3.0 | 3.0 |

RigidFilm Specifications(,,)

| MachineⅠ | Machine Ⅱ | ||

| Smooth Films | Matte Films | Smooth Films | |

| 0.030-0.044 | - | - | 120-130 |

| 0.045-0.069 | - | - | 120-130 |

| 0.070-0.149 | 175-195 | 170-1395 | 120-130 |

| 0.150-0.249 | 180-200 | 180-195 | 120-130 |

| 0.250-0.349 | 180-200 | 180-195 | 120-130 |

| 0.350-0.500 | 180-200 | 180-195 | 120-130 |

| 0.501-0.649 | 180-200 | 180-195 | - |

| 0.650-0.800 | 170-190 | - | - |

| 0.801-1.000 | 160-175 | - | - |

PVC Rigid Film and Sheet

| Code No. | Major Application | Characteristics | Thickness (mm) |

| 2VVVD | Deep mold forming | Good formability | 0.1~0.8 |

| 2VVVG | General vacuum forming | Great formability, impact resistance and good chemical resistance | 0.09~0.8 |

| 2VVVB | Battery packaging | Clear, high impact resistance and good formability | 0.1~0.8 |

| 2VVVS | Box lid | Non-whitening while folding, fit for processing round tube lids but with poor flow mark control than 2VBBB | 0.09~0.8 |

| 2VBBB | Box lid | Non-whitening while folding, fit for processing round tube lids | 0.09~0.8 |

| 2VBBF | Box lid folding | Fit for angular type packaging box | 0.10~0.5 |

| 2VFFA | Photo album | High-frequency welding | 0.07~0.15 |

| 2VFFB | Folding box | Great fold forming, high transparency | 0.10~0.5 |

| 2VFFF | Fruit trays | Good for speedy and extensive forming | 0.10~0.18 |

| 2VFVG | General food pack | Good formability | 0.09~0.8 |

| 2VSSA | Photo album | Good transparency, high toughness | 0.05~0.1 |

| 2VSSC | Card case | High gloss, high transparency, good impact resistance | 0.10~0.8 |

| 2VSSG | General stationery | Great printability and flatness, good for hot press lamination | 0.04~0.8 |

| 2VSSR | Spiral binder | Opaque, bright color, good dimensional stability and toughness | 0.30~0.8 |

| 2VSSS | Stress whitening tapes | Great whitening effect and toughness | 0.15~0.3 |

| 2VSSP | Light accumulation | Effect of keeping light | 0.07~0.2 |

| 2VLLL | Card overlay | Matte, translucent, good laminability and layflat quality | 0.04~0.2 |

| 2VLLT | Floor tile overlay | Good laminability, both layflat quality and abrasion resistance are great | 0.04~0.2 |

| 2VPPG | General printing | Good printability, also good formability | 0.25~0.8 |

| 2VPPL | Labels | Bending resistance, high toughness, good printability and laminability | 0.25~0.8 |

| 2VPPP | P laying cards | Good printability and stiffness, bending resistance, high opacity | 0.20~0.4 |

| 2VPPS | Synthetic paper | Paper imitation, good printability and ink dries rapidly | 0.08~0.6 |

| 2VPPT | Card core sticking | Non-lead formula, with the same characteristics as 2VPPL | 0.25~0.8 |

| 2VDDC | Ceiling lamination | Deep and vivid embossed grain | 0.05~0.15 |

| 2VDDD | Carved door | Vivid and lifelike colors and grains, good shallow formation | 0.25~0.6 |

| 2VDDE | Edging strip | High impact resistance and laminability | 0.25~0.6 |

| 2VDDL | Lampshade | Soft color, even light transparency, good printability | 0.15~0.4 |

| 2VDDP | Plate lamination | Great layflat quality, good laminability | 0.05~0.2 |

| 2VMMD | Christmas decoration | Bright color, good smoothness | 0.035~0.2 |

| 2VMMF | Food packing | Food grade metallized films, good formability | 0.09~0.5 |

| 2VMMS | Sequins | High gloss, good impact resistance | 0.10~0.3 |

| 2VMMV | Vacuum forming | High gloss | 0.20~0.5 |

| 2VWWC | Cooling tower plate | High heat distortion resistance, good formability | 0.20~0.75 |

| 2VWWW | Waste water treatment | Good chemical and heat distortion resistance, good formability | 0.20~0.75 |

| 2VZZC | Christmas tree leaves | Lifelike color, even dullness, good recoverability | 0.04~0.25 |

| 2VZZD | Christmas tree leaves | Non-whitening, with the same characteristics as 2VZZC | 0.04~0.25 |

| 2VZZJ | Insulation cover materials | Good weather resistance, combustion resistance | 0.27~1.0 |

| 2VZZM | Vacuum metallizing | Good transparency, excellent vacuum metallizing | 0.035~0.05 |

As the proportion of plasticizer used differs,polyvinyl chloride film can be divided into rigid PVC film and flexible PVCfilm. 2/3 polyvinyl chloride films used today are rigid PVC films. Our companyis a rigid transparent PVC film supplier in China. With high strength, goodtoughness, long service life, no toxicity and odor, our products are usuallyused for rigid plastic packaging. The appearance of our PVC film is comparableto that of cellophane. However, it is available at much lower prices.

Links:https://www.globefindpro.com/products/89871.html

-

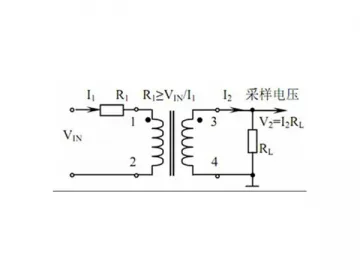

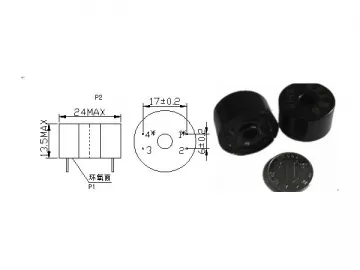

120 OHM Mini Voltage Transformer

120 OHM Mini Voltage Transformer

-

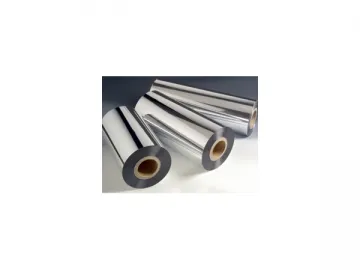

Metallized PET Film

Metallized PET Film

-

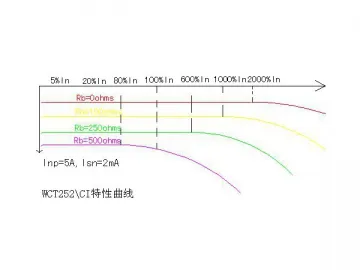

5A Mini Wire Lead Current Transformer

5A Mini Wire Lead Current Transformer

-

10A Mini Wire Lead Current Transformer

10A Mini Wire Lead Current Transformer

-

Transparent Soft PVC Film

Transparent Soft PVC Film

-

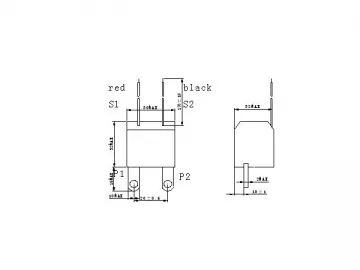

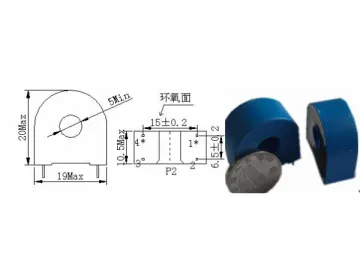

T10 Mini Split Core Current Transformer

T10 Mini Split Core Current Transformer

-

DJRFS200 Industrial Heat Sink

DJRFS200 Industrial Heat Sink

-

80 OHM Voltage Transformer

80 OHM Voltage Transformer

-

260 OHM Mini Voltage Transformer

260 OHM Mini Voltage Transformer

-

Cylinder Packaging

Cylinder Packaging

-

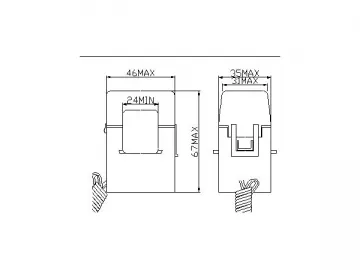

T24 Mini Split Core Current Transformer

T24 Mini Split Core Current Transformer

-

Embossed Rigid PVC Film

Embossed Rigid PVC Film