Ceramic Fiber Board

Ceramic Fiber Board

Our ceramic fiber board is made fromceramic fiber bulk and inorganic binders through vacuum molding. Thus our boardcould maintain good shape as well as a good mechanical strength in ahigh-temperature. Our modern production line works under automatic control.Our ceramic fiber board varies in different temperatures of 1050℃,1260℃,1400℃and1500℃.

Our product features a smooth surface, accurate size and even density. It alsoenjoys a low thermal conductivity and low shrinkage, as well as a good thermaland chemical stability. The high pressure resistance and corrosion resistancealso ensure the lifetime of our product. Meanwhile, our product owns excellenttensile thus you can easily cut it. Those properties make our product a goodchoice as a back lining material of high temperature furnace, boiler, waterheater and ceramic kilns. It can also be the backup insulation material inhigh-temperature condition.

Technical Specification of Ceramic FiberBoard

| Model (Density : 280kg/m3) | ALT –CGB1-1 | ALT-CGB2-1 | ALT –CGB3-1 | ALT –CGB4-1 | |

| Model (Density : 280kg/m3) | ALT –CGB1-2 | ALT-CGB2-2 | ALT –CGB3-2 | ALT –CGB4-2 | |

| Model (Density : 280kg/m3) | ALT –CGB1-3 | ALT-CGB2-3 | ALT –CGB3-3 | ALT –CGB4-3 | |

| Classification Temp ℃ | 1050 ℃ | 1260 ℃ | 1400 ℃ | 1500 ℃ | |

| Thermal Shrinkage (%) | 900 ℃× 24h ≦ -2.5 | 1100 ℃× 24h ≦ -2 | 1200 ℃× 24h ≦ -2 | 1350 ℃× 24h ≦ -2 | |

| Thermal Conductivity w/(m·.k) | At 600 ℃ | 0.080-0.085 | 0.086-0.087 | 0.083-0.085 | 0.083-0.085 |

| At 800 ℃ | 0.112-0.116 | 0.106-0.108 | 0.101-0.105 | 0.101-0.105 | |

| Compression Strength (Mpa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | |

| Size (mm) | L 400-40000mm × W 300-1200mm × T 10-100mm. Can be customized according to your requirements | ||||

| Density ( kg/m3 ) | 220 kg/m3 280 kg/m3 320 kg/m3 | ||||

| Package | Carton or Pallet | ||||

| Quality System Certificate | ISO9001-2000 | ||||

Links:https://www.globefindpro.com/products/89923.html

-

Ceramic Fiber Module

Ceramic Fiber Module

-

Custom Shaped Ceramic Fiber Products

Custom Shaped Ceramic Fiber Products

-

Bio-soluble Fiber Bulk

Bio-soluble Fiber Bulk

-

2-5mA Wound Primary Current Transformer

2-5mA Wound Primary Current Transformer

-

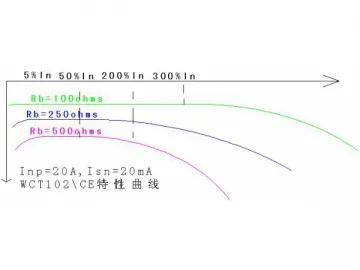

20mA Wound Primary Current Transformer

20mA Wound Primary Current Transformer

-

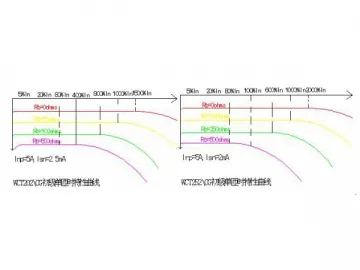

320 OHM Wound Primary Current Transformer

320 OHM Wound Primary Current Transformer

-

120 OHM Wound Primary Current Transformer

120 OHM Wound Primary Current Transformer

-

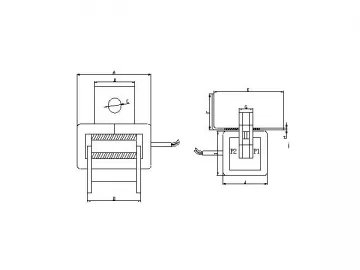

600A Generator Current Transformer

600A Generator Current Transformer

-

Toroidal Power Transformer

Toroidal Power Transformer

-

1.5A 3 Phase Current Transformer

1.5A 3 Phase Current Transformer

-

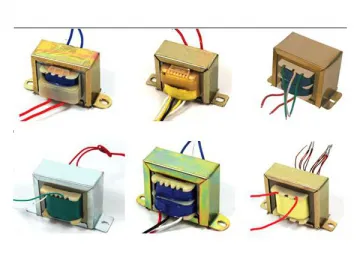

Lead Wire Power Transformer

Lead Wire Power Transformer

-

DR Inductor

DR Inductor