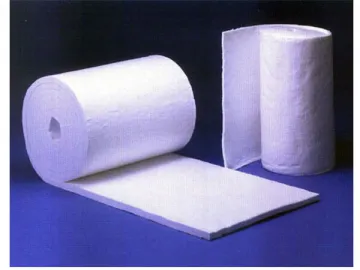

Ceramic Fiber Blanket

Ceramic Fiber Blanket

Our ceramic fiber blanket features a good strengthand resilience. Made via double needing, our product enjoys a flat surface aswell as a convenience in installation and maintenance. With a low thermal conductivity, low heat capacity, as wellas a good chemical and thermal stability, our product is a sound insulationmaterial as well as shock-absorbing material. Made from general fiber bulk byspinning and injection molding, our ceramic fiber blanket doesn’t contain anybonding agent.

Our product can be used as linings of boiler and water heater. It can also bethe sealing and insulation fillings in high-temperature as well as aerospaceindustry. It can also be used as the heat insulation material of the pipes,etc. Moreover, it can be the raw materials for modules.

Technical Specification of Ceramic Fiber Blanket

| Model (injection) | ALT-CGTP-1 | ALT-CGTP-2 | ALT-CGTP-3 | ALT-CGTP-4 | ALT-CGTP-5 | |||||

| Model (spin) | ALT-CGTS-1 | ALT-CGS2-2 | ALT-CGTS-3 | ALT-CGTS-4 | ALT-CGTS-5 | |||||

| Classification Temp ℃ | 1050 | 1260 | 1400 | 1400 | 1500 | |||||

| Working Temp | < 900 | 1100 | 1200 | 1200 | 1350 | |||||

| Density Kg/m3 | TS | TP | TS | TP | TS | TP | TS | TP | TS | TP |

| 64 -128 | 96 -160 | 64 -128 | 96 -160 | 64 -128 | 96 -160 | 64 -128 | 96 -160 | 64 -128 | 96 -160 | |

| Thermal Shrinkage %) | 900 ℃ X24H ≤ -3 | 1100 ℃ X24H ≤ -3 | 1200 ℃ X24H ≤ -3 | 1200 ℃ X24H ≤ -3 | 1350 ℃ X24H ≤ -3 | |||||

| Thermal Conductivity ( w/n.k ) (Density128Kg | 0.09 ( 400 ℃) 0.176 ( 600 ℃) | 0.09 ( 400 ℃) 0.22 ( 1000 ℃) | 0.132 ( 600 ℃) 0.22 ( 1000 ℃) | 0.132 ( 600 ℃) 0.22 ( 1000 ℃) | 0.16 ( 600 ℃) 0.22 ( 1000 ℃) | |||||

| Tensile Strength Mpa | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | 0.08-0.12 | |||||

| Size ( mm ) | Regular Size 7200/7320/7620 × 610 × 25,3600/3660/3810x610x50 ; or as clients’dimension | |||||||||

| Package | Woven Bag or Carton | |||||||||

| Quality System Certificate | ISO9001-2000 | |||||||||

Links:https://www.globefindpro.com/products/89950.html

-

50A Zero Phase Current Transformer

50A Zero Phase Current Transformer

-

Purple Makeup Box

Purple Makeup Box

-

Four Wheel Makeup Case Kit

Four Wheel Makeup Case Kit

-

Gold Color Makeup Box

Gold Color Makeup Box

-

Double Layer Silver Jewelry Case

Double Layer Silver Jewelry Case

-

Fashion Model Pattern Luggage Case

Fashion Model Pattern Luggage Case

-

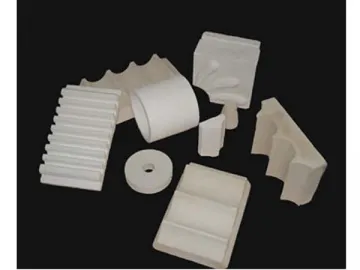

Custom Shaped Bio-soluble Fiber Product

Custom Shaped Bio-soluble Fiber Product

-

400A Generator Current Transformer

400A Generator Current Transformer

-

Kitty Pattern Luggage Case

Kitty Pattern Luggage Case

-

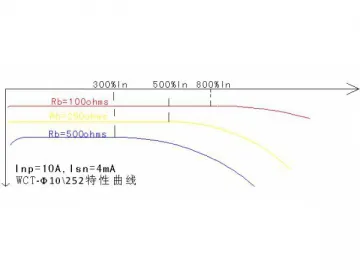

Φ10 Mini Wire Lead Current Transformer

Φ10 Mini Wire Lead Current Transformer

-

2mA Wound Primary Current Transformer

2mA Wound Primary Current Transformer

-

Bio-soluble Fiber Blanket

Bio-soluble Fiber Blanket