Steel Plate Hardening Complete Equipment

This equipment can be used for bending the steel plate. It adopts IGBT power module made by Siemens of Germany and a series resonant half-bridge circuit mode. And its power factor is up to 98% which is more energy-saving than traditional available silicon with 25-30 %. The size of the equipment is small, so it can be installed easily. Steel plate hardening complete equipment has perfact automation, such as automatic protection features of overvoltage, overcurrent, overheating, water and other, heating by divided into periods or continuous, stepless power, ing by pneumatic, PLC control, stepless speed and closed-loop temperature control, etc. All of these can make sure the heating consistency of each workpiece.

The Application Scopes of t

Application: heating, bending and hardening the whole steel plate

Steel plate size: length × width × thickness (mm)

617 × 250 × 13

617 × 250 × 16

617 × 250 × 19

Efficiency of hardening: 1piece of steel plate/min

Material of the steel plate: 30GM

Heating temperature: 900℃-930℃

HRC: 48℃-52℃

Composition of Steel Plate Hardening Complete Equipment

1.XZ-600KW solid power supply

Model | Power | Frequency | Maximum input current | Input voltage | Water pressure | Circuit mode | Power factor |

XZ-600 | 600KW | 6-8 KHZ | 900A(Single phase ) | 380V-400V | 0.15Mpa | IGBT series connection | 98% |

2.LBL-7 closed cooling system

Number | Cooling capacity Kcal/h | Fan flow m3/h | Working flow m3/h | Diameter of water pipemm | Capacity of circulating water tank L | Weight kg | Size L×W×H mm |

LBL-7 | 225000 | 38000 | 25-36 | 76 | 500 | 1800 | 2550 × 1300 × 2200 |

3.PLC control feeder machine

Our machine is a simple integrated PLC designed by Omron. The machine contains the E-type and N -type CPU units. E-type CPU unit can control the machine by the order of basic, move, arithmetic and contrast, as well as N-type CPU units can connect to the programmable terminal, the frequency converter and servo drives. It has the 20/30/40 point type CPU and standard USB port of CP1E/CP1L/CP1H. It also has the N-type built-in RS232 port with positioning function of expanded 2 serial. You can operat the machine conveniently with 2-axis output control scale which is up to 100KHz and easy to see the floating-point operations of I/O status.

4.1set of far-infrared temperature control system

Infrared temperature measurement system is equipped with online non-contact thermometer. The infrared thermometer is a kind of photoelectric sensor which can detect thermal radiation. The sensor with a million second response speed can detect the moving object conveniently. And the system is controlled by temperatureand its temperature probe is fixed, so it avoids the difference between actual temperature and required temperature due to grid voltage fluctuation, human factors and the intensity of light. In this way, the quality of product can be improved. Technical parameters of Infrared temperature measurement system are as follows:

Measuring range : 200℃-1200℃

Measuring precision: ±10℃

Repeatability precision: ±0.5%

Response time: 10ms (95%)

Collimation: laser aiming (2 laser, the maximum output power of 1mw, 650nm)

Links:https://www.globefindpro.com/products/90120.html

-

UPVC Profile for Window and Door

UPVC Profile for Window and Door

-

40KW Power Supply of 3 Phase MF Induction Heating

40KW Power Supply of 3 Phase MF Induction Heating

-

PE Protective Film for Aluminum Profile, Aluminum Window

PE Protective Film for Aluminum Profile, Aluminum Window

-

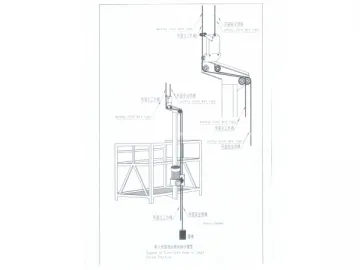

Single Suspended Work Platform

Single Suspended Work Platform

-

UPVC Shutter

UPVC Shutter

-

Wood Aluminum Composite Windows and Doors

Wood Aluminum Composite Windows and Doors

-

Window Glass Protection Film

Window Glass Protection Film

-

30KW Power Supply of Three Phase Induction Heating

30KW Power Supply of Three Phase Induction Heating

-

Aluminum Retractable Fly Screen

Aluminum Retractable Fly Screen

-

160KW Power Supply of 3 Phase HF Induction Heating

160KW Power Supply of 3 Phase HF Induction Heating

-

Protective Film for Deep Drawing Stainless Steel

Protective Film for Deep Drawing Stainless Steel

-

Exterior Shutter, Aluminum Sun Shade Window

Exterior Shutter, Aluminum Sun Shade Window