Gear Quenching Complete Equipment

is a dedicated equipment for high-frequency gear quenching. It quenchs the gear by rotating and heating the gear. It selects IGBT power, which makes it more energy-saving. Energy monitoring and cooling system can guarantee the quality of each product. 50mm-¢ 500mm, and its thickness should be within 10mm-50mm.

Composition and Parameters of Gear Quenching Complete Equipment

1. XG-200KW high frequency power

Product number | Power | Frequency | Input current | Input voltage | Transformer |

XG-200 High-frequency | 200KW | 15-30KHz | 300A | Three-phase 380-420V | Quenching dedicated |

2. ZSY-1000P CNC gear quenching equipment

Maximum turning diameter: 1000mm

Maximu of workpiece: 1.5-30mm/s

T

3.

Cooli 110000 Kcal/h

Working flow: 12-23 m3/h

Fan flow: 26400 m3/h

ulating wa: 400L

Size: 20 mm

Weight: 1000kg

4.

adopts infrared temperature measurement system. The infrared radiation thermometer uses on-line non-contact thermometer. It is a photoelectric sensor. This sensor of the system can detect the "thermal radiation". The intensity of infrared radiation varies with the temperature and material characteristics of an object. So our complete equipment can measure the temperature speedy and control gears’ heating temperature in high-precision by using this system, and avoids the instability of the product quality caused by using thermocouple. Thus using the infrared temperature measurement system can measure the consistency and the quality of the product.

5. Energy monitoring system

Gear quenching complete equipment has energy monitoring system. This system adopts the closed-loop control and not be affected by the voltage level, which can guarantee the energy consistency of each workpiece and the quality of each product. Firstly, the system will measure, display and record the operating voltage and current of equipment by computer. Then operating voltage and current would be entered into the computer after conversion and optical transmission. Later, the computer starts to compute.

Momentary power= Momentary voltage × momentary current

Momentary energy=Momentary power × heating time

W (t) = ∫ P (t) dt

The P is the time integral value from 0 to t. You can set maximum P and minimum P according to the workpiece process requirements, and the P is the upper and lower limits for the energy integral value. When the products are manufactured in large quantities, the system will compare each sample energy value with the P. If the value is within P, is qualified, if not, the workpiece is just under-burned or over-burned.

Links:https://www.globefindpro.com/products/90136.html

-

Installation Instructions of Invisible Screen

Installation Instructions of Invisible Screen

-

BOPP Aluminized Complex Film for PVC Window

BOPP Aluminized Complex Film for PVC Window

-

Protective Film for Acrylic Sheet, PVC/ABS Sheet

Protective Film for Acrylic Sheet, PVC/ABS Sheet

-

Floor Protection PE Film

Floor Protection PE Film

-

Casement Aluminum Windows and Doors

Casement Aluminum Windows and Doors

-

100KW Power Supply of 3 Phase MF Induction Heating

100KW Power Supply of 3 Phase MF Induction Heating

-

500KW Power Supply of High Frequency Induction Heating

500KW Power Supply of High Frequency Induction Heating

-

Wood Aluminum Composite Windows and Doors

Wood Aluminum Composite Windows and Doors

-

UPVC Shutter

UPVC Shutter

-

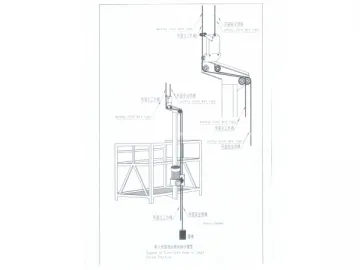

Single Suspended Work Platform

Single Suspended Work Platform

-

PE Protective Film for Aluminum Profile, Aluminum Window

PE Protective Film for Aluminum Profile, Aluminum Window

-

40KW Power Supply of 3 Phase MF Induction Heating

40KW Power Supply of 3 Phase MF Induction Heating