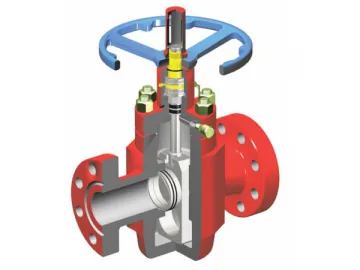

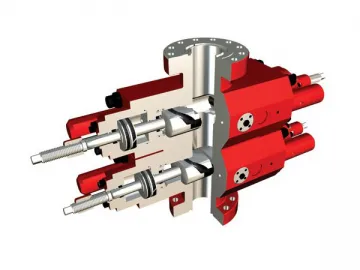

Double Ram Blowout Preventer

Double Ram Blowout Preventer

The double ram blowout preventer is a U-shaped blowout preventer designed with a hydraulic opening system and the shut-off damper. And the damper can be easily changed.

The shut-off pressure provided by the controlling system of the double ram blowout preventer is used to close the damper and open the end cover as well. If it is utilized to open the end cover, the closing pressure will shut off the damper. After the cover bolt is removed, the end cover can be opened with the pressure. As soon as the end cover is fully opened, the damper can be removed out of the blowout preventer. On the top of each damper are threads used for installing suspension clasps so that the damper can be conveniently suspended.

By contrast, the opening pressure offered by the control system of the double ram blowout preventer is utilized to open the damper as well as to close the end cover. When closing the end cover, the opening pressure helps open the damper. And the end cover will be closed as long as the damper is changed, driven by the opening pressure. Before being moved into the double ram blowout preventer, the damper is pulled out in the position near the end cover. This makes the damper clear of the vertical through-hole and away from the drill pipe. When fully closed, the end cover is fastened with the bolt.

Links:https://www.globefindpro.com/products/90382.html