Choke Manifold

Choke Manifold

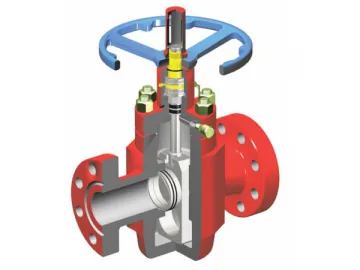

The choke manifold we supply here is composed of the throttle valve, sluice valve, pipe line, pipe fitting and pressure gage. It also meets the API Spec 16C standard and has gained the API Spec 16C certification whose number is 0019.

Working Principle

The choke manifold is necessary equipment in controlling the well kick and pressures. When the pressure rises, the casting pressure can be regulated through discharging the well fluid by opening or closing the throttle valve on the choke manifold. And if the casting pressure rises too high, then the throttle valve can directly open the well for gushing.

Operation Requirements

1. Working pressures of all components on the choke manifold have to match with those of preventers. And this product comes in five grades for option, 14MPa, 21MPa, 35MPa, 70MPa and 105MPa and bespoke grade is also available.

2. Working temperature gage has to be installed. And the working pressure of the choke manifold ranges from 2,000psi to15, 000psi.

3. This product should be installed in the places easily accessible for operators. And it has to undertake pressure test and the sealing test pressure is supposed to equal to the rated working pressure.

4. Pipe lines are required to be as straight as possible. And its bended parts should be fitted with the 120°cast steel elbow. And its aperture should be large enough and nominal diameter ranges from 2-1/16” ~ 4-1/16”.

5. The choke manifold should have excellent performance at low temperatures in winter.

Links:https://www.globefindpro.com/products/90390.html