Induction Melting Furnace

Induction Melting Furnace

Product Number: GW3/IGBT-2000-0.2-B

Specifications of Induction Melting Furnace

No. | Item | Data |

01 | Rated Capacity of Furnace Body (Molten Steel) | 3t |

02 | Rated Power of Medium Frequency Power Supply | 2000kW |

03 | Maximum Output Power(Per Furnace) | 1800kW |

04 | Rated Frequency | 200Hz |

05 | Working Temperature | 1600 °C |

06 | Melting Rate(excluding the rated time spent in feeding, beneficiating and densifing materials, the third cycle of furnace reloading time as well as auxiliary time.) | 3t/h |

07 | Power Consumption (excluding the rated time spent in feeding, beneficiating and densifing materials, and the third cycle of furnace reloading time as well as auxiliary time.) | 600kWh/t |

08 | Cooling Water Consumption by the Medium Frequency Power | 30m3/h |

09 | Cooling Water Consumption by Each Furnace | 60m3/h |

10 | Size of the Furnace Body | 3100 ×2800 ×2850 |

11 | Weight of One Furnace Body | 12.5t |

12 | Size of the Rectifier Cabinet | 2000×1200×2600 |

13 | Size of the Inverter Cabinet | 3200×1200×2600(2 Sets) |

14 | Weight of the Power Supply Cabinet | 6t |

15 | Dedicated Oil-immersed Rectifier Transformers | ZS-2200-10/0.475, 3-phase/50Hz/2200KVA,Primary Voltage: 10KV,Secondary Voltage: 475V ± 5% △ / YO-11 Wiring, Impedance: 5.8% |

Features

1. The induction melting furnace is electricity-saving and friendly to the power grid. The adoption of the series circuit makes the reactive current very small, thus significantly reducing the power consumption. And the power factor of the whole equipment is maintained over 0.95 in the overall process of operation, not requiring any compensation measure.

2. The induction melting furnace has an excellent start-up performance. This means that it can be started up under any circumstances with the success rate nearly up to 100% by the implementation of soft start and soft shutdown systems. In the case of whether startup or shutdown, or protection action of automatic shutdown, this furnace can automatically enter a state of either soft start or soft shut down. Therefore, this induction melting furnace can be started up or shut down under any circumstance of full power, full voltage or frozen furnace, while meantime, the necessary protection is ensured reliable and accurate.

3. It also features high reliability. Being a kind of self-closing device, the IGBT rarely fails inverse transformation and the protections are also temporary. Furthermore, the series inverter circuit completed with the IGBT features much simpler lines than any other method. Also, the IGBT can easily achieve dual track power output, bringing convenience for operators to handle and maintain this induction melting furnace. Managed with the high technology, the IGBT can be semi-permanently used.

4. It is so easy to maintain that general operating electricians can do such work after a systematic training.

Links:https://www.globefindpro.com/products/90403.html

-

Vacuum Induction Smelting Furnace

Vacuum Induction Smelting Furnace

-

Coated Sand Production Line

Coated Sand Production Line

-

Shot Blasting Machine

Shot Blasting Machine

-

Small CCM / Small Continuous Casting Machine / Conticaster

Small CCM / Small Continuous Casting Machine / Conticaster

-

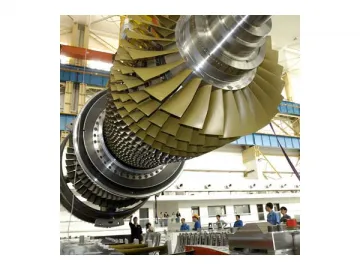

Combustion Turbine Blades

Combustion Turbine Blades

-

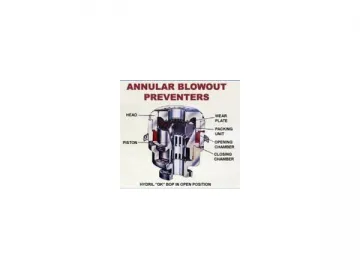

Blowout Preventer

Blowout Preventer

-

High Voltage Motor

High Voltage Motor

-

Vacuum Carbon Sintering Furnace

Vacuum Carbon Sintering Furnace

-

Printed Velboa Fabric

Printed Velboa Fabric

-

Polyurethane Insulation Steel Pipe

Polyurethane Insulation Steel Pipe

-

Gilding Suede Fabric

Gilding Suede Fabric

-

12 Ton Ladle Refining Furnace

12 Ton Ladle Refining Furnace