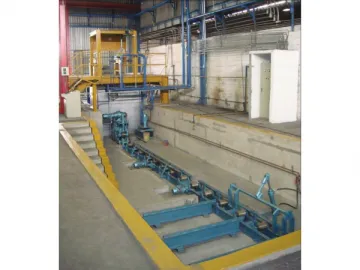

Small CCM / Small Continuous Casting Machine / Conticaster

Small CCM / Small Continuous Casting Machine / Conticaster

The small continuous casting machine features the flexible dummy bar and a tundish fixing bracket. And one withdrawal and straightening unit can cast only one strand of billets each time. The strand cutting is manually operated. This product is particularly suitable for small steel mills with annual yield of the billets or reinforcing steel bars ranging from 20,000t to 50,000t.

Technical Parameters of Small Continuous Casting Machine

1. Radius of the Casting Machine: 2.0m

2. Billet Size: 60 m3

3. Set Length of the Billet: 3.0m

4. Water Consumption by Crystallizer: 80t/h

5. Secondary Cooling Water: 15t/h

6. Mechanical Cooling Water: 10t/h

7. Power Consumption by On-line Equipment: 40KW

8. Power Consumption by Water and Gas Systems: 80KW

Supply List of On-line Equipment of Small Continuous Casting Machine

No. | Item | Quantity | Remark |

1 | Tundish Mounting Bracket | 1 |

|

2 | Tundish | 1 |

|

3 | 60 m3Crystallizer | 1 |

|

4 | Crystallizer Cover | 1 |

|

5 | Vibration Device | 1 |

|

6 | Secondary Cooling Spray Pipe and Rack | 1 |

|

7 | Secondary Cooling Guiding Section | 1 |

|

8 | Secondary Cooling Steam Discharging System | 1 |

|

9 | Withdrawal and Straightening Machine | 1 |

|

10 | Dummy Bar | 1 |

|

11 | Dummy Bar Head | 1 |

|

12 | Storage Device of Dummy Bar | 1 |

|

13 | Conveyor Roller | 1 |

|

14 | Billet Roller | 1 |

|

15 | Billet Shifter | 1 |

|

16 | Cooling Bed | 1 |

|

17 | Overflow Tank | 1 |

|

18 | Hydraulic Station System | 1 |

|

19 | Cooling Water Distribution System | 1 |

|

20 | EIC System | 1 |

|

A | Electricity Control Equipment |

|

|

B | Field Instruments |

|

|

23 | Steel Platform | 1 |

|

24 | Installation Materials | ||

A | Electricity and Instrument System Materials | ||

B | Hydraulic Piping Materials | ||

C | Cooling Water System Materials | ||

Links:https://www.globefindpro.com/products/90408.html

-

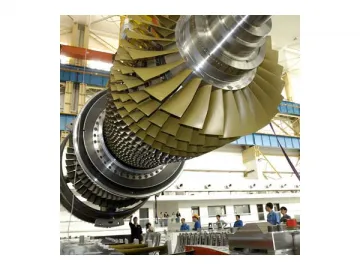

Combustion Turbine Blades

Combustion Turbine Blades

-

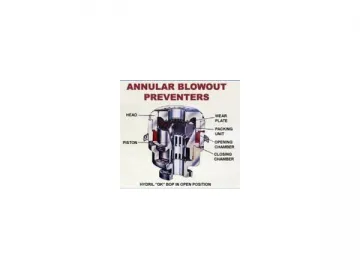

Blowout Preventer

Blowout Preventer

-

Vacuum Induction Furnace

Vacuum Induction Furnace

-

Titanium Alloy Turbine Blade

Titanium Alloy Turbine Blade

-

Dual Track Electric Furnace

Dual Track Electric Furnace

-

2 Ton Electric Arc Furnace

2 Ton Electric Arc Furnace

-

Shot Blasting Machine

Shot Blasting Machine

-

Coated Sand Production Line

Coated Sand Production Line

-

Vacuum Induction Smelting Furnace

Vacuum Induction Smelting Furnace

-

Induction Melting Furnace

Induction Melting Furnace

-

High Voltage Motor

High Voltage Motor

-

Vacuum Carbon Sintering Furnace

Vacuum Carbon Sintering Furnace