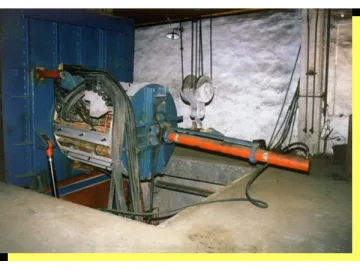

Cone Crusher

Cone Crusher

The cone crusher has standard and brachycephalic subtypes. Generally, the standard type features larger feeding and discharging granularity while the other type has steeper cone and smaller feeding granularity. Thus, the former type is usually used for coarse and medium crushing applications while the latter for medium and fine crushing applications.

The cone crusher is sealed with the lubricating grease, thus making the water supplying and drainage systems free from stoppage. The spring safety system can protect this machine from damage caused by overload. This product features higher crushing rate, great efficiency, larger processing capacity as well as low operation costs, convenient adjustment and economical price. Due to the superior quality material and reasonable construction, the cone crusher can crush materials into uniform granularity, which helps reduce the circulating load to a large extent. Furthermore, hydraulic cavity cleaning system is adopted in large or medium cone crushers, greatly reducing the downtime. And the cavity is available in a variety of specifications to suit customers’ specific requirements.

The cone crusher is ideally suited for crushing ores and rocks with medium or above medium hardness degrees used in metallurgy, building materials, chemical and other industries.

Links:https://www.globefindpro.com/products/90461.html