Trommel Screen

Trommel Screen

YTS trommel screen isregularly used in material classification and ore washing processes, and isapplicable for both wet and dry type materials. It is easy for installation,maintenance and operation, and generates low noise and low dust duringoperation. It requires small installation space and small installation slope,and features steady operation and high screening efficiency. The trommel screenwon’t get blocked easily.

Our trommel screen is composed of an electric motor, speed reducer, rotarydrum, machine frame, seal cover, and material feeding and discharging holes. Theelectric motor functions to drive the drum to rotate with the help of speedreducer and coupling. The rotary drum is installed in a certain inclinationangle. Due to the inclination and rotation of the drum, the materials on thescreen surface overturn and move as well. Thus, qualified materials will passthrough the screen mesh and collected, and unqualified particles will bedischarged from the rotary drum end.

Technical Parameters of the TrommelScreen

| Model | Drum Size ( mm) | Feeding Size ( mm) | Screen Mesh ( mm) | Capacity (t/h) | Rotary Speed ( r/min) | Power ( kw ) | Weight ( t) |

| YTS800×2000 | Φ800×2000 | ≤10 | 1-10 | 10-15 | 20 | 1.5 | 1.6 |

| YTS 1000×2400 | Φ1000×2400 | ≤15 | 1-15 | 20-50 | 15-19 | 4 | 3.3 |

| YTS 1200×3000 | Φ1200×3000 | ≤20 | 1-15 | 50-100 | 13-18 | 5.5 | 4.3 |

| YTS 1500×3000 | Φ1500×3000 | ≤20 | 1-20 | 100-150 | 13-18 | 7.5 | 5.3 |

| YTS 1500×4500 | Φ1500×4500 | ≤20 | 1-20 | 100-200 | 13-18 | 7.5 | 6 |

| YTS 1800×4800 | Φ1800×4800 | ≤30 | 1-30 | 200-250 | 13-18 | 7.5 | 7.5 |

| YTS 2000×4000 | Φ2000×4000 | ≤50 | 1-50 | 200-300 | 13-16 | 11 | 9 |

To suit customers’ application demands, we can offer trommel screens withvaried drum size and screen mesh. Details are available in the followingspecification chart.

Links:https://www.globefindpro.com/products/90821.html

-

ESYS-1010 Reminder Sound Box

ESYS-1010 Reminder Sound Box

-

Hydraulic Briquette Machine

Hydraulic Briquette Machine

-

ESYS-4006 Music and Dancing Lion Module /Talking Toys

ESYS-4006 Music and Dancing Lion Module /Talking Toys

-

ESYS-1002 Animal Sound Box

ESYS-1002 Animal Sound Box

-

ESYS-2006 Recording Voice Module

ESYS-2006 Recording Voice Module

-

Centrifugal Concentrator

Centrifugal Concentrator

-

ESYS-6010 Customized Sound Greeting Card

ESYS-6010 Customized Sound Greeting Card

-

ESYS-1012 Small Music Box for Toy

ESYS-1012 Small Music Box for Toy

-

Leaching Tank

Leaching Tank

-

ESYS-4005 Dancing Music Module for Toy /Music Toys

ESYS-4005 Dancing Music Module for Toy /Music Toys

-

ESYS-2002 Cards Sound Chip

ESYS-2002 Cards Sound Chip

-

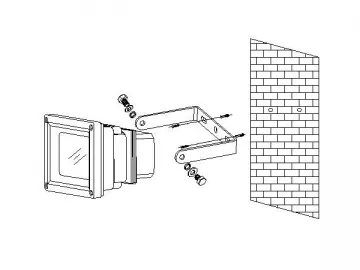

10W LED Flood Light

10W LED Flood Light