Rotary Magnetic Drum

Rotary Magnetic Drum

The rotary magnetic drum is also calleda magnetic pulley and is classified into permanent magnetic drum andelectromagnetic drums. It is ideal for iron removal in mineral processing,ceramic, coal, mouldingsand, refractory material and other related industries. To meet customers’diversified application demands, we can offer rotary magnetic drums with drumdiameter from 400mm to 1000mm, and belt width from 500mm to 1200mm.

Structure and Working Processes

Our rotary magnetic drum is made up of the magnetic system, rotary drum, magnetyoke, aluminum ring, rubber belt, etc. Firstly, the mineral ores are fed ontothe rubber belt. When the belt surrounds and moves along with the drum, non-magnetic or weakmagnetic mineral ores will drop down from the belt due to gravity andcentrifugal force, while strongly magnetic mineral ores stick on the belttightly due to the magnetic force. When the belt moves to the bottom part ofthe magnetic drum, it will depart from thedrum and is unbendedfinally. Thus, the mineral materials stickedon the belt will fall down to a material container as a result of magneticforce weakening.

Technical Parameters of the RotaryMagnetic Drum

| Model | Drum Size (mm) | Belt Width (mm) | Magnetic Field Strength (Gs) | Feeding Size (mm) | Capacity (t/h) | Weight (kg) |

| CT-40/50 | Φ400×600 | 500 | 1550-3000 | ≤80 | ≤50 | 250 |

| CT-50/50 | Φ500×600 | 500 | 1600-3000 | ≤100 | ≤80 | 370 |

| CT-40/65 | Φ400×750 | 650 | 1550-3000 | ≤100 | ≤60 | 405 |

| CT-50/65 | Φ500×750 | 650 | 1600-3000 | ≤130 | ≤100 | 520 |

| CT-50/80 | Φ500×950 | 800 | 1550-3000 | ≤100 | ≤100 | 610 |

| CT-65/80 | Φ650×950 | 800 | 1650-3000 | ≤130 | ≤120 | 720 |

| CT-65/100 | Φ500×1150 | 1000 | 1700-3000 | ≤130 | ≤120 | 710 |

| CT-65/100 | Φ650×1150 | 1000 | 1700-3000 | ≤170 | ≤160 | 1200 |

| CT-80/120 | Φ800×1400 | 1200 | 1800-3000 | ≤100 | ≤160 | 1500 |

| CT-100/120 | Φ1000×1400 | 1200 | 1800-3000 | ≤200 | ≤200 | 1890 |

Links:https://www.globefindpro.com/products/90836.html

-

ESYS-5004 LED Display Module

ESYS-5004 LED Display Module

-

ESYS-4001 Music Dancing Movement Dolls /Sound Plush Toys

ESYS-4001 Music Dancing Movement Dolls /Sound Plush Toys

-

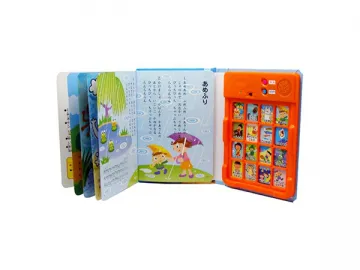

ESYS-3004 Audio Book

ESYS-3004 Audio Book

-

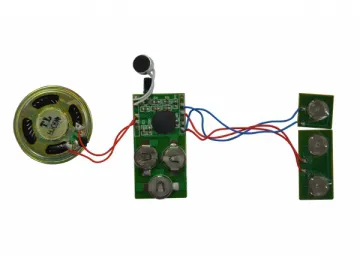

ESYS-3003 Custom Voice Book

ESYS-3003 Custom Voice Book

-

Vibration Feeder

Vibration Feeder

-

ESYS-6014 Sound Pen

ESYS-6014 Sound Pen

-

ESYS-1001 Sound Module Box

ESYS-1001 Sound Module Box

-

ESYS-6006 Talking Fly Swatter

ESYS-6006 Talking Fly Swatter

-

ESYS-1009 Music Press Button

ESYS-1009 Music Press Button

-

ESYS-3007 Recordable Sound Book

ESYS-3007 Recordable Sound Book

-

ESYS-2005 Recordable Voice Chip

ESYS-2005 Recordable Voice Chip

-

ESYS-3005 Speaking Book

ESYS-3005 Speaking Book