6S Shaking Table

6S Shaking Table

Our 6S shaking table is ideal for separation andcollection of tungsten ore, tin ore, tantalum ore, niobium ore, and other raremetal ores and precious metal ores with particle size between 0.02mm and 2mm. As a kind of gravity separation equipment, it isalso applicable for iron, manganese ore and coal, etc. It has high separationefficiency and easy for operation and adjustment, offers high concentrationratio, and can get the ore concentrate and tailings at a stroke.

The shaking table is designed with an inclined tablewhich moves back and forth asymmetrically. The mineral materials are deliveredto the table surface from the upper part of the table, and meanwhile, the waterfrom the water tank is supplied laterally. Due to gravity of mineral ores, thelateral rinsing of water, and the inertial force and friction caused by themovement of the table, the mineral ores are layered and move in either lengthwise or crosswise direction along the inclined table according to theirspecific gravity and particle size. Finally, the ores form into a sector shapeon the shaking table surface, and is divided into ore concentrate, middling andtailings from the top to the bottom part of the sector.

Technical Parameters of the 6S Shaking Table

| Type | Table Size | Max. Feeding Size | Stroke | Water Consumption | Table Area | Bed Fracture Shape | Power | Weight | ||

| Length | Head Width | End Width | ||||||||

| Unit | mm | mm | mm | mm | mm | t/d | m2 | Kw | Kg | |

| For Coarse Material | 4450 | 1855 | 1546 | 2 | 16-22 | 80-150 | 7.6 | Rectangle | 1.1 | 780 |

| For Fine Material | 4450 | 1855 | 1546 | 0.5 | 11-16 | 30-60 | 7.6 | Saw tooth | 1.1 | 780 |

| For Slime Material | 4450 | 1855 | 1546 | 0.15 | 8-16 | 10-17 | 7.6 | Triangular | 1.1 | 780 |

According to the ore feeding hole position, the 6S shakingtable can be classified into left-side feeding and right-side feeding shakingtables. To suit customers’ demands, the product can be designed with a specialdevice to adjust the table inclination angles.

Links:https://www.globefindpro.com/products/90853.html

-

Hot Dip Galvanized Steel Sheet

Hot Dip Galvanized Steel Sheet

-

Hot Rolled Steel and Steel Coil

Hot Rolled Steel and Steel Coil

-

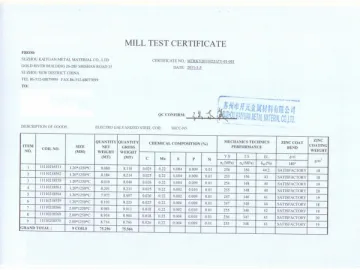

Electro Galvanized Steel Sheet

Electro Galvanized Steel Sheet

-

400GPD SE RO Water Purifier

400GPD SE RO Water Purifier

-

Vibration Screen

Vibration Screen

-

Rotary Ore Washing Machine

Rotary Ore Washing Machine

-

400G Direct Flow Water Purifier

400G Direct Flow Water Purifier

-

PR75-C-E-1 75G RO Water Purifier

PR75-C-E-1 75G RO Water Purifier

-

Electro Galvanized Steel and Galvanized Coil

Electro Galvanized Steel and Galvanized Coil

-

CU-H4 Compact Ultrafiltration Water Purifier

CU-H4 Compact Ultrafiltration Water Purifier

-

ESYS-6005 Music /Sound Bottle Opener

ESYS-6005 Music /Sound Bottle Opener

-

ESYS-6004 LED Keychain

ESYS-6004 LED Keychain