Rotary Ore Washing Machine

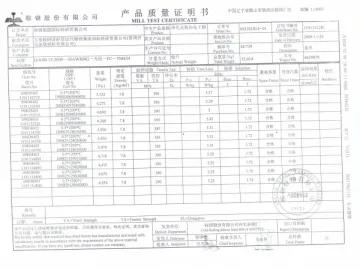

Rotary Ore Washing Machine

GTX rotary ore washing machine isdesigned based on advanced international technologies and can be used forseparating slime from sand and stone materials. Mounted with two or three layertrommel screen inside the rotary drum, the rotary orewashing equipment is able to classify materials into two or three grades. It isusually used before beneficiation, so as to improve the efficiency of nextprocessing step.It is ideal for separating of manganese ore, iron ore, limestone, tungsten ore,silica ore, etc.

Our rotary ore washing machine is mainly composed of the rotary drum, trommel screen, gear, electric motor and speed reducer. Tosuit customers varied demands, we can also offer equipment with chaintransmission or tire transmission, in addition to standard gear transmission.

After raw materials are fed into the rotary drum where they are washed bywater, the slime on stone and sand materials can be washed away and dissolvesin the water. Thus, the stone and sand materials are cleaned, and then areclassified by the trommel screens and dewatered. Finally, they can becollected from the discharging hole of the rotary ore washing machine. Thewater with dissolved slime is discharged from the baffle plates with holes atthe feeding or discharging end.

Technical Parameters of the Rotary Ore Washing Machine

| Model | Drum Dimension (mm) | Screen Size (mm) | Rotation Speed (r/min) | Feeding Size (mm) | Water Consumption (m3/h) | Capacity (t/h) | Power (kw) | Weight (t) |

| GTX1030 | Φ 1000 × 3000 | ≤ 20 | 27.9 | ≤ 80 | 1 | 40 | 15 | 3.8 |

| GTX1230 | Φ 1200 × 3000 | ≤ 25 | 27.6 | ≤ 100 | 1.3 | 70 | 22 | 4.7 |

| GTX1430 | Φ 1400 × 3000 | ≤ 25 | 27.6 | ≤ 100 | 1.5 | 80 | 22 | 4.9 |

| GTX1545 | Φ 1500 × 4500 | ≤ 25 | 21 | ≤ 160 | 1.7 | 120 | 30 | 6.9 |

| GTX2265 | Φ 2200 × 6500 | ≤ 50 | 19 | ≤ 230 | 1.8 | 180 | 37 | 15.9 |

Links:https://www.globefindpro.com/products/90859.html

-

Faucet

Faucet

-

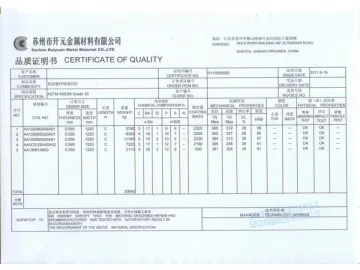

Electrical Steel Coil and Sheet Steel

Electrical Steel Coil and Sheet Steel

-

Pre Coated Steel Coil and Sheet Steel

Pre Coated Steel Coil and Sheet Steel

-

Other Small Parts

Other Small Parts

-

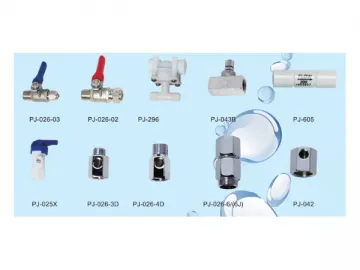

Fittings

Fittings

-

Cold Rolled Steel Coil and Sheet Steel

Cold Rolled Steel Coil and Sheet Steel

-

Vibration Screen

Vibration Screen

-

400GPD SE RO Water Purifier

400GPD SE RO Water Purifier

-

Electro Galvanized Steel Sheet

Electro Galvanized Steel Sheet

-

Hot Rolled Steel and Steel Coil

Hot Rolled Steel and Steel Coil

-

Hot Dip Galvanized Steel Sheet

Hot Dip Galvanized Steel Sheet

-

6S Shaking Table

6S Shaking Table