HDA3308XR-P Inkjet Printing Machine

HDA3308XR-P Inkjet Printing Machine

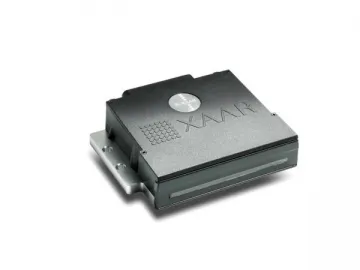

The HDA3308XR-P inkjet printing machine made by us introduceseight XAAR 382 35/60 PL steel print head made in Britain and each one has 382orifices with droplet of 35 Pl or 60 Pl for option. The print head it adopts ownsmax printing accuracy at 1440dpi, tough steel structure and high printingspeed. The XAARbranded print head our machine uses has two working states with the printingwidth of 53.7mm andthe adjustable ignition frequency of 9.5 KHz or 7 KHz. User can shut theconnector of liquid and electronic parts to make sure the convenience andsecurity of integrating print headswhich helps to lower the purchase cost of customer.

Technical Specification

| Model | HDA3308XR-P(8*XAAR382 35/60PL) | ||

| Resolution | Up to 1440dpi | ||

| Printhead | XAAR382 35/60PL | ||

| Media Printing Width | 3.2m(126 inch) | ||

| Speed | 2pass 72m 2 / h, 3pass 45m 2 / h, 4pass 30m 2 / h | ||

| Color | C, M, Y, K/ C, M, Y, K, L C, LM | ||

| Width | 3.2m (126 inch) | ||

| Media Handling | Roll to roll | ||

| Media | Paper / advertising banner / PVC / adhensive vinyl and so on | ||

| Ink | Eco-solvent and solvent-based cmyk | ||

| Image Format | TIFF / JPG / EPS / PDF / BMP | ||

| Printing Software | Use photoprint with PRT format to print | ||

| Control System | Windows 2000 workstation/Windows XP/Vista/Window7 | ||

| Operation Environment | Power: AC( single phase), 50HZ/60HZ 220V( ± 10%)>15A | ||

| Distortion: < 0.5% | Temperature: 20 ℃ ~ 30 ℃ | Humidity: 40% ~ 70% | |

| Dimension( LxWxH) | 4850X740X1100mm | ||

| Weight | 450kg | ||

Besides the traits of print head, our inkjet printing device is good atprinting on lamp house cloth, ad cloth, PVC film, vehicle wrap, networkmaterial, etc. It can do CMYK or CMYK.LC.LM printing at a highest speed of 60㎡/h. Its acceptable max media thicknesscan reach 3.2M and itsink is 60% cheaper, but its speed is 35% higher, than that of other printerwith the same specification. The special edge leaving and punching functionsbased on the USprinting software, photoprint, do help to save more time withenhancing the work efficiency by 15%. Smart ink supply system can remove therisk of ink shortage. In addition, we introduce edge feathering craft to removethe strips which occur during the passes.

Links:https://www.globefindpro.com/products/91001.html

-

ES17201 conductive castor

ES17201 conductive castor

-

3.5 Inch Sensor Digital Photo Frame

3.5 Inch Sensor Digital Photo Frame

-

ES12104 Conductive Nylon glove with carbon fiber 防静电碳纤维涂指手套

ES12104 Conductive Nylon glove with carbon fiber 防静电碳纤维涂指手套

-

16W Sensor LED Ceiling Light

16W Sensor LED Ceiling Light

-

18W Sensor LED Down Light

18W Sensor LED Down Light

-

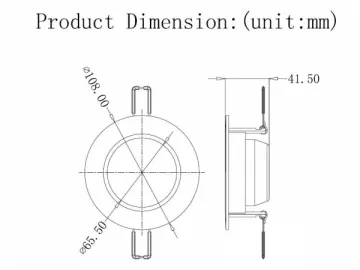

12W Sensor LED Down Light

12W Sensor LED Down Light

-

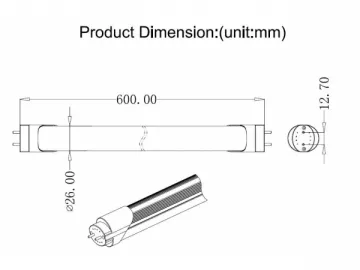

8W T8 Sensor LED Tube

8W T8 Sensor LED Tube

-

ES17107 ESD chair

ES17107 ESD chair

-

ES12303 Touch Screen Glove 触摸屏手套

ES12303 Touch Screen Glove 触摸屏手套

-

9W Sensor LED Down Light

9W Sensor LED Down Light

-

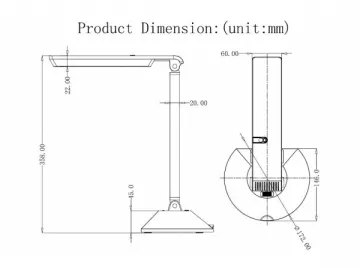

Intelligent Sensor LED Table Lamp

Intelligent Sensor LED Table Lamp

-

ES17103 ESD chair

ES17103 ESD chair