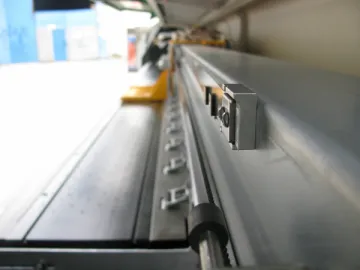

HDC3316KM Inkjet Printing Machine

HDC3316KM inkjet printing machine from us is equipped with sixteen Konica branded 512 42/14 Pl print heads, abbreviated for KM 512 print head. These print heads can work together at a high printing speed of 160㎡/h. It introduces ink piezoelectric charging method, which can make electric field according to the order from controller to inject tiny ink drops by changing the form of ink chamber. Moreover the public ink chamber utilizing, piezoelectric type start, and shear mode can make the printer quite power saving.

Technical Specification

Drive Mode | Piezoelectric and Smart | |

Nozzle Resolution | 180dpi×2 line = 360dpi | |

Nozzle Number | 256 ×2 line = 512 | |

Nozzle Spacing | 70.5μm =(141μm 2 line) | |

Droplet | 42pl | 14pl |

Transmitting Frequency | 7.6kHz | 12.8kHz |

Printing Width | 36.1mm | |

Dimensions( W×D×H) | 67mmW×40mmD×72mmH | |

Solvent-based Ink | Available | Available |

UV Ink | Available | Available |

Oil Ink | Available | Available |

Max droplet in grey scale | - | 3 drops |

Internal Ink | Available | Available |

Model | HDC3316KM(16*512 14PL) | ||

Resolution | Up to 1440dpi | ||

Printhead | KONIA 512 14PL | ||

Media Printing Width | 3.2m (126 inch) | ||

Speed | 2pass 160m 2 / h, 3pass 120m 2 / h, 4pass 65m 2 / h | ||

Color | C , M , Y , K/ C , M , Y , K , L C , LM | ||

Width | 3.2m (126 inch) | ||

Media Handling | Roll to roll | ||

Media | Paper / advertising banner / PVC / adhensive vinyl and so on | ||

Ink | Eco-solvent and solvent-based cmyk | ||

Image Format | TIFF / JPG / EPS / PDF / BMP | ||

Printing Software | Use photoprint with PRT format to print | ||

Control System | Windows 2000 workstation/Windows XP/Vista/Window7 | ||

Operation Environment | Power: AC( single phase ) 50HZ/60HZ, 220V( ± 10%)>15A | ||

Distortion: <0.5% | Temperature: 20 ℃ ~ 30 ℃ | Humidity: 40% ~ 70% | |

Dimension ( LxWxH ) | 4760X940X1500mm | ||

Weight | 550kg | ||

Our inkjet printing device can run the KM 512 print head in shear mode and supply ink in piezoelectric and smart way. It uses has resolution of 360 dpi which allows 512 tiny nozzles to be fixed in the head and our inkjet printing machine can work with numbers of heads bound together at the same time. Thus it can make our machine run with lower power consumption. The head in our machine set two ink droplet options for user, L or M, in which L means 42pl and M means 14pl. Moreover the printer can print out more smooth color grading effect when user chooses the four grey level driving models under M. In addition this KM 512 print head can be fed with super solvent ink which is widely used in wide format printer and viscous UV which ink which can be heated to 55 Celsius degrees to avoid viscosity by its inner H type heater.

In terms of structure design, our printing device has a special print head installation design named wing, which can do great help to trim the print heads, do undirected printing by organizing several unit heads and exchange a unit head with another one inside. For application, our inkjet printing machine can be used in many printing ways such as lamp case cloth, ad cloth, PVC film, vehicle wrap, network, and etc.

Links:https://www.globefindpro.com/products/91029.html

-

SGVT-01 Vehicle GPS Tracking System

SGVT-01 Vehicle GPS Tracking System

-

Leather Printing Machine

Leather Printing Machine

-

SRM802 Embedded Wireless Data Transmitter Module

SRM802 Embedded Wireless Data Transmitter Module

-

MAKECOLOR UVFR2512 UV Printer

MAKECOLOR UVFR2512 UV Printer

-

Custom Color Box

Custom Color Box

-

MAKECOLOR UVF2512 UV Printer

MAKECOLOR UVF2512 UV Printer

-

Spice Glass Jar

Spice Glass Jar

-

SGTS-100 Vehicle GPS Tracking Platform

SGTS-100 Vehicle GPS Tracking Platform

-

Wood Cork Stopper

Wood Cork Stopper

-

Vodka Glass Bottle

Vodka Glass Bottle

-

Plastic Bottle Cork Stopper

Plastic Bottle Cork Stopper

-

Tequila Glass Bottle

Tequila Glass Bottle