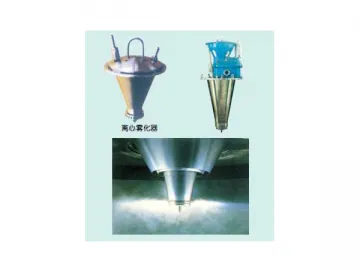

Centrifugal Spray Dryer

LPG CentrifugalSpray Dryer

The LPG centrifugal spraydryer provides high drying speed. Because the production procedures are simple,it is easy to operate and control. Our dryer is especially suitable for dryingthe heat sensitive materials, and the final products achieve high quality, highpurity, good uniformity, mobility, and dissolving capacity.

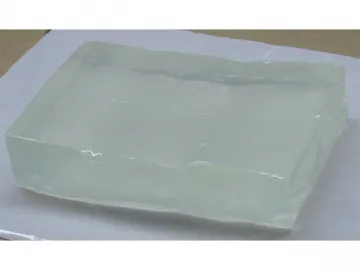

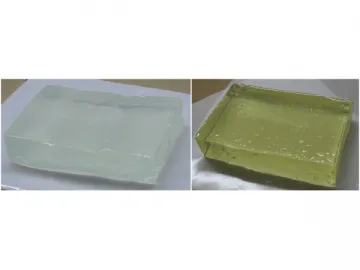

Ourcentrifugal spray dryer adopts the spray drying technology, which is a widelyapplied process in liquid solidification and drying industry. It is suitablefor producing powder, particle, or block solid products from the materials,such as solution, emulsion, soliquoidand pumpable paste liquid.This drying machine is great for applications where the particle size anddistribution of the final products, their residual moisture content, thestacking density and the particle shape must meet the precise standards.

Working Principle

The air filtered and heated enters into the distributor on the top of thecentrifugal spray dryer, and then enters into the drying room in the spiralform and uniformly. While passing through the high speed centrifugal atomizeron the top of the tower, the material liquid will rotate and be sprayed intothe extremely fine mist liquid beads. During the very short time of contacting theheat air, the materials can be dried into the final products, and thendischarged continuously from the bottom of the drying tower and the whirlseparator. The waste gas will be discharged from the blower.

Features

1. The surface area of the material beingsprayed will increase greatly. Thus, 95% ~98% of water can be evaporatedquickly in the hot air flow. In several seconds, the drying is achieved.

2. The liquid with 40-60 % moisture content can be dried into the powder orparticle products at one time. For special materials, the moisture contents mayreach 90%. After the drying, there is no need for smashing and sorting,reducing the operation procedures and enhancing the product purity.

3. The product particle diameters, looseness and water contents can be adjustedby changing the operation condition in a certain scope.

Our centrifugal spray dryer is suitable for drying a wide variety ofmaterials in many industries:

1. Chemical industry: sodium fluoride, alkaline dyestuff and pigment, dyesintermediates, compound fertilizer, formaldehyde silicic acid, catalyst, sulfuric acid agent, aminoacid, and so on.

2. Plastic resin industry: AB, ABS emulsion, urea-formaldehyde resins, phenolic resins, polyethylene,polyvinyl chloride, etc.

3. Foodstuff industry: high fat milk powder, cocoa powder, milk replacer, egg white (yolk), oats,chicken juice, coffee, instant tea, seasoning meat, protein, soybean, peanutprotein, corn syrup, corn starch, glucose, pectin, maltose, sorbic acid potassium, etc.

4. Ceramic industry: aluminum oxide,ceramic tile material, magnesium oxide, talc, etc.

Parameters of Centrifugal Spray Dryer

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note: the waterevaporation capacity is related to material properties and theinlet and outlet temperature.

Flow Chart:4()

1. air filter

2. heater

3. hot air distributor

4. drying room

5. filter

6. pump

7. nozzle

8. whirl separator

9. blower

10. material liquid groove

,:spray dryermachine、fluid bed dryerflash dryer。LPG,。5,。140350,8090。(),,、、。95%,。

Links:https://www.globefindpro.com/products/91272.html