RTS Annealing Furnace

RTS Annealing Furnace

The RTS pushrod type resistance annealing furnace isapplicable to the spheroidization and isothermal annealing of mechanical parts, likebearing rings. Parts processed by this furnace has uniform texture and stablequality, and the depth of decarburization, hardness and microstructure all meetnational JB/T1255-2001 standard.

Opening andclosing of the furnace doors, feeding, discharging and other actions areconducted automatically and circularly, yielding high efficiency. Adoptingeffective thermal insulation materials, the furnace lining significantly savesenergy. The front and back doors are not open at the same time, which reducesthe flow of furnace gases, thus reducing the oxidation of the workpiece surface.

| Type | Work size W×L×H(mm) | Rated heating power (kw) | Maximum working temperature (℃) | Maximum productivity (kg/h) |

| RTS8-58 ×820 ×44 | 580 ×8200 ×440 | 120 | 850 | 250 |

| RTS8-58 ×1100 ×44 | 580 ×11000 ×440 | 140 | 850 | 300 |

| RTS8-58 ×1300 ×44 | 580 ×13000 ×440 | 160 | 850 | 350 |

| RTS8-58 ×1590 ×51 | 580 ×15900 ×510 | 225 | 850 | 500 |

| RTS8-58 ×1740 ×51 (With front and back replacement rooms) | 580 ×17400 ×510 | 225 | 850 | 500 |

RTSheat treatment furnace,、。、、、。,。。,,。

forging furnace5,RTS8-58x1740x51,xx580x17400x510,850,500,。

Links:https://www.globefindpro.com/products/91560.html

-

Floor Decking Roll Forming Machine

Floor Decking Roll Forming Machine

-

Stainless Playground

Stainless Playground

-

KS-868 Wireless GSM Alarm System

KS-868 Wireless GSM Alarm System

-

Container Corner Casting

Container Corner Casting

-

Metal Floor Deck Roll Forming Machine

Metal Floor Deck Roll Forming Machine

-

Container Industry

Container Industry

-

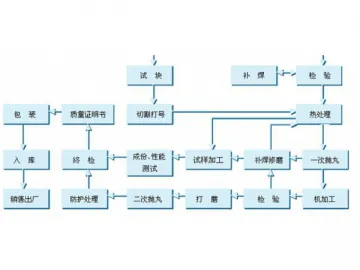

Surface Treatment

Surface Treatment

-

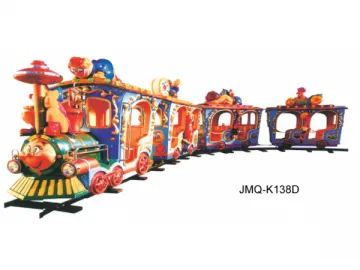

Electric Tourist Train

Electric Tourist Train

-

Shot Blasting Machine

Shot Blasting Machine

-

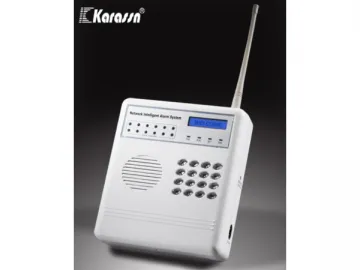

KS-898A Home Security Alarm System

KS-898A Home Security Alarm System

-

C Purlin Forming Machine

C Purlin Forming Machine

-

Granite Cutting

Granite Cutting