Floor Decking Roll Forming Machine

FloorDecking Roll Forming Machine

YXOOKM51-240-720 floor decking roll forming machineis mainly used to produce steel floor decking and can produce high qualityfloor decking which has advantages, such as no cutting deformation, highstrength, and a large working load.

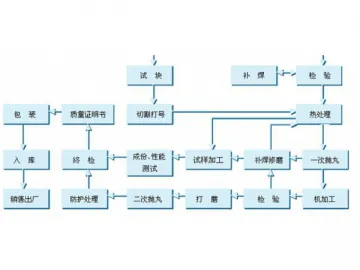

High qualitydesign, machine parts, and accessories contribute to the great performance ofour floor decking roll forming machine. The machine’s stand is made of H steeland is 14mm thickplate, so the rigidity and stability of the floor decking forming machine isvery high. The uncoiler has a load bearing capacity of 5tons. A guiding block is used to ensure that workpieces move in the straight line. The high-powered hydraulic motor providesenough power for the hydraulic system to cut pieces at a speed of up to 9m/min, providing high production efficiency.The cutter is made of Cr12 and is heat treated in order to give it a hardnessranging from 58° to 62°. The roller is made of 45# steel and is coated with a 0.05mm thick layer of chromium, so itsanti-corrosion ability is improved and the floor decking roll forming machineservice life is extended. A reliable PLC electric control system from Japanese Omron provides advantagessuch as high precision and fast speed regulation, and a frequency converter from Taian also contributes to fast and reliable speed regulation. Convenientand automatic control can be achieved with the help of a computer which displays text, and all forming processes can be executedsimultaneously.

1. Floor Decking Picture

Main Specifications

| Type | GL – I (YX51-240-720) | Application | ||

| Effective Width (mm) | 720 | |||

| Feeding Width (mm) | 1000 | |||

| Thickness (mm) | 0.8 | 1.0 | 1.2 | Steel Floor Decking |

| Section Inertia (cm4/m) | 52.8 | 64.55 | 76. 38 | |

| Section Resistance (cm3/m) | 16.45 | 20.69 | 26. 39 | |

2. Technical Specifications of Floor Decking Roll FormingMachine

| Forming type | Simultaneous forming | |

| Guide Rod | mm | φ 50 |

| Bearing Guide | mm | φ 40 |

| Shaft | mm | φ 70 |

| Motor Power of Machine | kW | 18.5 |

| Linear Speed | mm/min | 10000-12000 |

| Motor of Hydraulic Station | kW | 4 |

| Number of Stations |

| 27 |

| Rolling Thickness | mm | 0.8-1.2 |

| Material Uncoiling Width |

| 1000 |

| Cut-to-length Accuracy | mm | ± 1.5 |

| Overall Dimensions(L×W×H) | mm | 26000×1400×1400 |

| Weight | kg | 18000 |

Asa specialized floor decking roll forming machine manufacturer and supplier inChina, we at Huaheng alsoprovide an EPS sandwich panel production line, multithread flame cuttingmachine, Z purlin formingmachine, CNC flame plasma cutter, and more.

Links:https://www.globefindpro.com/products/91561.html

-

Stainless Playground

Stainless Playground

-

KS-868 Wireless GSM Alarm System

KS-868 Wireless GSM Alarm System

-

Container Corner Casting

Container Corner Casting

-

Metal Floor Deck Roll Forming Machine

Metal Floor Deck Roll Forming Machine

-

Container Industry

Container Industry

-

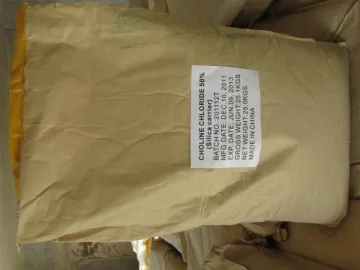

Choline Chloride 50% Silica Carrier

Choline Chloride 50% Silica Carrier

-

RTS Annealing Furnace

RTS Annealing Furnace

-

Surface Treatment

Surface Treatment

-

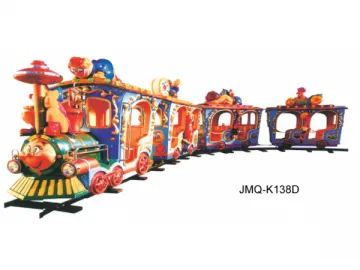

Electric Tourist Train

Electric Tourist Train

-

Shot Blasting Machine

Shot Blasting Machine

-

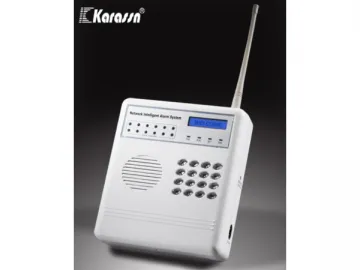

KS-898A Home Security Alarm System

KS-898A Home Security Alarm System

-

C Purlin Forming Machine

C Purlin Forming Machine