EPS Sandwich Panel Production Line

EPS SandwichPanel Production Line

The EPS sandwich panel production line can producesandwich panel with inner material of EPS foam. EPS material is formed by meansof processes like pre-foam, curing, forming, heating and cutting, and hasfeatures such as heat insulation, being moisture-proof, light weight, and very strong. The production line first coilsthe steel plate and glues the steel plates and EPS foam together, so we cancreate architectural materials with great strength that are light weight andprovide heat insulation. Therefore, our EPS sandwich panel is widely used infactory workshops, large warehouses, temporary buildings, refrigeration houses,and other buildings.

The EPSsandwich production line is 40000mmlong, 4500mm wide, 2800mm high, and weighs 16t.It is efficient and capable of yearly producing 600,000 square meters of EPS sandwichpanels in 40 to 250mmthicknesses.

The total power of the EPS sandwich panel production line is 30kW. The formingmachine is equipped with a gear reducer and a 2.2 kW electric motor. Theworking speed is 4.27 m/min and can vary from 0 to 4m/min according to requirements aftervariable frequency speed regulation technology is adopted. The laminatingsystem is equipped with a micro cycloidal pinwheelgear reducer and a 2.2 kW electric motor. The working speed is 3.38 m/minand working speed can vary from 0 to 4 m/min after variablefrequency speed regulation technology is adopted. The optimal speed ranges from 2.5 to 3.5m/min for EPS sandwich panel productionand for production of other panels the speed is relatively lower.

The EPS sandwich panel production line uses K-9adhesive metering pump, which has advantages such as low speed and highmeasuring accuracy. In fact, this pump can output 0.1-2.0 kg adhesive per minute and the average amount of adhesive whichis needed is 0.25-0.4 kg/m².So we can produce numerous EPS sandwich panels for reasonable cost.

Weare an experienced EPS sandwich panel production line manufacturer and supplierin China.We provide a variety of products, including CNC plasma cutting machine, C purlin forming machine, multithread flame cutting machine,and more.

Links:https://www.globefindpro.com/products/91570.html

-

Steel Shot

Steel Shot

-

Rear Corner Post Inner

Rear Corner Post Inner

-

Steel Floor Deck Roll Forming Machine

Steel Floor Deck Roll Forming Machine

-

P3 Indoor Full Color LED Display Screen

P3 Indoor Full Color LED Display Screen

-

Metal Deck Roll Forming Machine

Metal Deck Roll Forming Machine

-

Feed Grade Yeast Powder 45%, 50%, 55%, 60%

Feed Grade Yeast Powder 45%, 50%, 55%, 60%

-

Choline Chloride 50%,60% Vegetable Carrier

Choline Chloride 50%,60% Vegetable Carrier

-

Hairdesign Power Hair Molding Clay

Hairdesign Power Hair Molding Clay

-

Choline Chloride 50% Silica Carrier

Choline Chloride 50% Silica Carrier

-

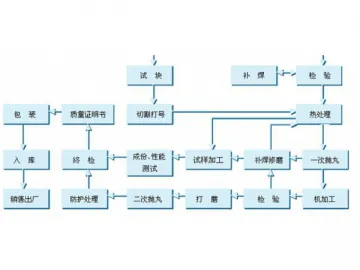

Container Industry

Container Industry

-

Metal Floor Deck Roll Forming Machine

Metal Floor Deck Roll Forming Machine

-

Container Corner Casting

Container Corner Casting