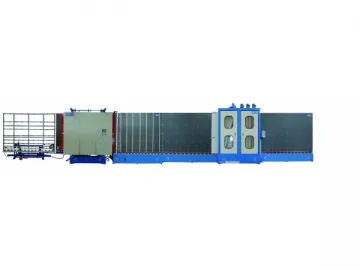

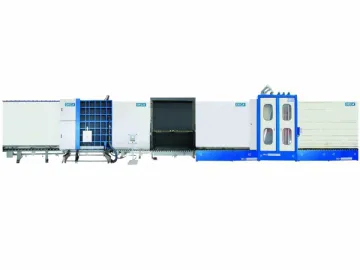

2000 Insulating Glass Production Line

LBZ2000PC Vertical Insulating glass flat press production line

LBZ2000PC Vertical Insulating glass flat press production line is suitable for producing insulating glassunit equipped with aluminum spacer, such as the standard double IGU, tripleIGU, Shaped IGU and optional stepped insulating glass unit. Adopting theworld's latest design concepts and advanced processing technology, thisinsulating glass production line has various advantages. For example, it isenvironmentally friendly, energy-saving, highly efficient, cost-effective, andfeatures powerful function, easy operation, low power consumption, convenientmaintenance, etc. Hence, our insulating glass production line is the idealequipment for large-scale insulating glass manufactures.

Our insulatingglass production line is composed of the feed conveyer, washing and dryingstation, output conveyer, aluminum frame mounting machine, assembly and press robot,and titling table. Therefore, it can realize automatic convey, washing anddrying of glass, positioning of aluminum frame, as well as automatic assembly,flat press and lay and output of the insulating glass unit.

1. Equipped with thickened sound-absorbingcotton, the drying section and glass outlet of the insulating glass productionline features reduced noise. The use of auxiliary security door can also wellprevent the glass. Formed by laser cutting and CNC bending at a time, the allstainless steel air-knife with even knife edge and long service life produces highair pressure and low noise.

2. The machine body of thewashing and drying station is made of stainless steel, and the transportmechanism with waterproof bearings and flexible devices can convey 3-12mm glasswith no adjustment required. The independent nozzle with free-to-adjust angleand fixed retainer spring can realize fanwise sputtering and can be dismountedfor easy cleaning. In addition, the air blower of the insulating glass productionline makes use of the circulating air heating method to ensure good dryingeffects.

3. Welded by thickenedsteel frame, the pressing robot of the insulating glass production linefeatures high strength, small deformation, and good stability. The high-strengthinner plate with a thickness of 30mm is connected and fixed to the steel frame. The pressing robot is also especiallyequipped with an advanced adjustable mechanism to ensure that any externalfactor will not influence the flatness of plate and allows for uniform andaccurate press of insulating glass at all times .

4. The lateral and under positioning of aluminum frame can be manuallycontrolled. The locating piece of aluminum frame adopts the buffer structure ofrubber block and compressed spring, and can be freely adjusted according to thethickness of the glass.

5. The under positioning mechanism of glass is equipped with the cylinder andservo electric handspike. The cylinder works when the insulating glassproduction line produces normal insulating glass, and the cylinder and electrichandspike work together when the machine makes stepped unit. This flexible workingmode of the insulating glass production line greatly improves workingefficiency and lowers failure rate.

Technical features

1) The insulating glassproduction line is controlled by the programmable logic controller (PLC)throughout the production process.

2) The digital input and outputcontrol system provides high degree of automation and user-friendly operation.

3) Each section of the productionline can be manually or automatically controlled with ease.

4) The touch screen can timelydisplay the working status and accurately determine the operating conditions ofthe equipment.

5) The soft brushes are adoptedfor cleaning of ordinary glass and on-line low-E glass.

6) This production line can also automaticallyrecognize the coated glass and low-emissivity glass.

7) Our insulating glass production line adopts anenergy-efficient working mode. For example, it starts automatically when thereare glasses waiting for handling and shuts down when glasses are removed.

8) the insulating glassproduction line can be folded and detached for convenient installation and easytransportation. Bythe way, all the distribution wires are designed with special high-strengthprotection tubes for safety.

9) The back wheel of theinsulating glass production line is designed with shaft sleeve structure, andthe outer layer is made of polyurethane for good wear resistance.

10) Itproduces no scratch on the glass, and features smooth transmission with lownoise. The transport back plate uses high-intensity polymerization boardprocessed with plastic spraying, ensuring beautiful appearance, as well asanti-aging and anti-corrosive performance.

11) Thetransport roller of the insulating glass production line is made ofpolyurethane and the shaft core featuring screw connection can effectivelyavoids the occurrence of off-axis.

12) Italso enjoys the features of good wear resistance, durable operation, and longservice life. The automatic expansion clamp is also equipped in the insulatingglass production line to realize stable and reliable convey of glass.

Technical Parameters of the InsulatingGlass Production Line

Water supply: 0.5T/hPH=7±1 (conductivity: ≤40μs)

Power supply: Three phase and four wire 380V/50 Hz

Air supply: Displacement0.80m/min, rated pressure 1.0MPa, motor power≥7.5KW

Total power: 25KW

Washing speed: 2~10 m/min

Maximum working speed: 45m/min

Production cycle: 23~30s(1000mm×1000mm)

No sealant output:1000~1200pcs /8h

Glass processing dimension:

Min: 450mm×280 mm

Max: 2000mm×2500mm standard(lengthened: 2800mm)

Washing glass thickness:3~12mm standard

Max. insulating glass thickness: 40mm standard (60mmoptional)

Stepped IG dimension:150mm×50mm

Transport roller height: 520mm

Transport roller spacing:184mm

Transport rollerdiameter: 57mm

Back wheel material:polyurethane

Aluminum spacer width: 4~27mm

Tilting table height: 850mm

Angle of inclination:84°

Overall dimension: 16400mm×2500mm×3087mm(L×W×H)

Total weight: ≈5600kg

Key components of the Insulating GlassProduction Line

| No. | Name | Brand |

| 1 | PLC | Japan OMRON |

| 2 | Inverter | Japan OMRON |

| 3 | Touch screen | Taiwan EVIEW |

| 4 | Vertical gear reducer | Taiwan ZHIBAO |

| 5 | Horizontal gear reducer | Taiwan ZHIBAO |

| 6 | Brush motor | Taiwan ZHIBAO |

| 7 | Servo motor | Germany KINCO |

| 8 | Pneumatic solenoid valve | Taiwan AirTAC |

| 9 | Ball screw pair | Taiwan ABBA |

| 10 | Linear guide pair | Taiwan HIWIN |

| 11 | Hydraulic component | Taiwan |

| 12 | Hydraulic component | France SCHNEIDER |

| 13 | Photoelectric switch | Germany SICK |

| 14 | Micro switch | Taiwan TEND |

As a major insulating glass production line manufacturer and supplier in China, ourcompany also offers sealant spreading machine, spacer bending machine, CNCglass cutting machine, glass loading machine, and much more.

Links:https://www.globefindpro.com/products/91592.html

-

Tube Solar Water Heater

Tube Solar Water Heater

-

Insulating Glass Production Line

Insulating Glass Production Line

-

CNC Plasma Cutting Machine

CNC Plasma Cutting Machine

-

Split Air Source Heat Pump

Split Air Source Heat Pump

-

Z Purlin Forming Machine

Z Purlin Forming Machine

-

Submerged Arc Welding Machine

Submerged Arc Welding Machine

-

Solar Collector

Solar Collector

-

Domestic All in One Hot Water Air Source Heat Pump

Domestic All in One Hot Water Air Source Heat Pump

-

Multithread Flame Cutting Machine

Multithread Flame Cutting Machine

-

2700 Insulating Glass Production Line

2700 Insulating Glass Production Line

-

Solar Water Heater

Solar Water Heater

-

Wooden Playground

Wooden Playground