CNC Plasma Cutting Machine

CNC Plasma CuttingMachine

The CNCplasma cutting machine is a piece of cutting equipment which can be used to cutcarbon steel plate, stainless steel plate, aluminum, copper and othernonferrous metals. Our company is ISO certified, and ourCNC plasma cutting machine meets the requirements of ISO8206 and JB/T5102-1999standards. As a result, our machinesare widely used in engineering machine, shipbuilding, the auto industry,pressure vessels, steel structures, and other industries.

Our CNC plasma cuttingmachine cuts metals in different thicknesses using a plasma torch. In thecutting process, inert gas is blown at high speed out of a nozzle, and anelectrical arc is formed through the gas from the nozzle to the surface beingcut, turning some of that gas to plasma. The metal is melted by heat producedby high temperature plasma electrical arc and removed by high speed plasmamovement. Compared with ordinary CNC cutting equipment, the CNC plasma cutteroffers many advantages, such as high cutting speed and small cuts.

1. MainConfigurations

| Mechanical Unit | Main Machine Span | 3/4/5/6/7/8m |

|

| Longitudinal Guide Length | 4/6/8/10/12/14/16/18/20/22/24m |

|

| Plasma Torch Number | 1-2 Units |

|

| Arc Height Adjustor | 1-2 Units |

|

| Drive Mode | Bilateral Drive |

|

| Transmission Mode | Belt (horizontal direction) Hanger (vertical direction) |

| Electrical Unit | CNC System | Imported from America |

|

| Motor | Imported from Japan |

|

| Reduction Box | Imported from Germany |

|

| Program Software | FASTCAM from Australia |

2. Technical Specifications of CNC Plasma Cutting Machine

| Item | Unit |

|

| Effective Cutting Width | m | 2.2/3.2/4.2/5.2/6.2/7.2 |

| Effective Cutting Length | m | 2/4/6/8/10/12/14/16/18/20/22 |

| Plasma Cutting Thickness | mm | 0.5-50 |

| Plasma Punching Thickness | mm | 0.5-25 |

| Plasma Cutting Speed | mm/min | 0-6000 |

| Torch Moving Distance | mm | 200 |

| Running Speed of Whole Machine | mm/min | 0-9000 |

| Speed Error | % | ≤±5 |

| Accuracy of Height Adjustment | mm | ≤±1 |

To ensure product quality, our company purchases the high quality parts fromsuppliers all over the world. For example, CNC system fromUSA Hypertherm, AC servomotor from Japan’sPanasonic, and reduction box from German Neugartall are used to make our high performance CNC cuttingmachine. The machine beam’s position can be adjusted to be perpendicular to therails every time the machine begins working, in order to maintain the machine’sprecision. Rails are made of bearing steel which is subjected to heat treatmentand chromate treatment, so that the rails are resistant to corrosion and aredurable. In addition, the rail surface is ground to a smooth finish to reduceresistance while the workpieceis moving. A wireless controller also makes it convenient to control the CNCplasma cutting machine.

Huaheng is a professional CNC plasma cuttingmachine manufacturer in China.We provide a wide range of products, including an assembling machine, straighteningmachine, metal deck roll forming machine, C purlin forming machine, and much more.

Links:https://www.globefindpro.com/products/91597.html

-

Split Air Source Heat Pump

Split Air Source Heat Pump

-

Z Purlin Forming Machine

Z Purlin Forming Machine

-

Submerged Arc Welding Machine

Submerged Arc Welding Machine

-

Assembling Machine

Assembling Machine

-

High Temperature Air Source Heat Pump

High Temperature Air Source Heat Pump

-

CNC Flame Plasma Cutter

CNC Flame Plasma Cutter

-

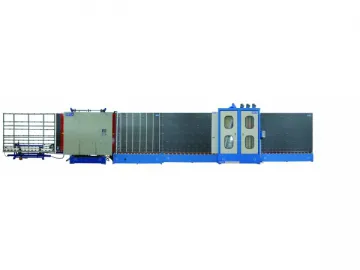

Insulating Glass Production Line

Insulating Glass Production Line

-

Tube Solar Water Heater

Tube Solar Water Heater

-

2000 Insulating Glass Production Line

2000 Insulating Glass Production Line

-

Solar Collector

Solar Collector

-

Domestic All in One Hot Water Air Source Heat Pump

Domestic All in One Hot Water Air Source Heat Pump

-

Multithread Flame Cutting Machine

Multithread Flame Cutting Machine