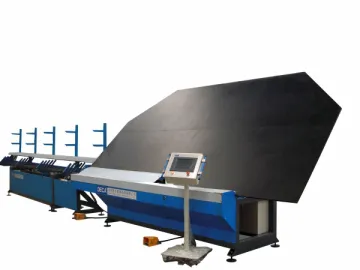

Automatic Spacer Bending Machine

BLQZ01 AutomaticSpacer Bending Machine

The BLQZ01 automaticspacer bending machine is used to bend the aluminum spacer of the insulatingglass unit. With powerful function and wide applicability, it replaces thetraditional corner key assembly, and can complete the production of variousaluminum spacer frames in the shape of convex polygon by using one piece ofspacer at one time. Due to our spacer bending machine, many aluminum spacers ofdifferent specifications and sizes can be bended, and aluminum spacers indifferent shapes can also be bended in succession. The bent spacer frame withimproved strength ensures good sealing effect and long service life of theinsulating glass. Ourspacer bending machine adopts PLC control system and user-friendly touch screeninterface. The servo feeding systemadopts CNC control, and the aluminum spacer can be feed automatically. Thecutting saw will avoid cutting spacer connectors intelligently. Thespacer bending machine also has four groups of storage location for storingspacers of different sizes. In addition, this machine can be adjusted to bendthe aluminum spacer of large size. A split bending protector made of stainlesssteel is also available.

Technical Parameters of the Automatic Spacer Bending Machine

Max. bending size:2000×2000mm

Min. bending size:250×250mm

Aluminum spacer width:5.5~24mm

Aluminum spacer transmissionspeed: 120m/min

Spacer frame error: ≤±0.5mm

Angle error: ≤±1°

Processing speed: ≤30pcs/s (1000×1000mm)

Air supply: Flow: 0.6m³/min,Air pressure≥0.8MPa

Total power: 3P380V 50HZ2.5KW

Dimension: 1050×2100×2200mm(L×W×H)

DECA is an automatic spacer bending machine manufacturer based in China.We provide a vast array of products including desiccant filling machine, butylextruder machine, auto sealing robot, glass loading machine, and more.

Links:https://www.globefindpro.com/products/91635.html

-

Glass Loading Machine

Glass Loading Machine

-

CNC Glass Cutting Machine

CNC Glass Cutting Machine

-

ST02 Sealant Spreading Machine

ST02 Sealant Spreading Machine

-

ST02A Sealant Spreading Machine

ST02A Sealant Spreading Machine

-

Glass Edge Finishing Machine

Glass Edge Finishing Machine

-

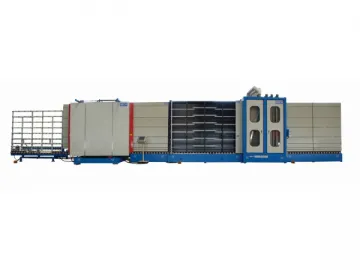

2500 Insulating Glass Production Line

2500 Insulating Glass Production Line

-

JT03 Butyl Extruder Machine

JT03 Butyl Extruder Machine

-

Horizontal Glass Washing Machine

Horizontal Glass Washing Machine

-

Automatic Desiccant Filling Machine

Automatic Desiccant Filling Machine

-

Gas Filling Machine

Gas Filling Machine

-

Glass Edge Deletion Machine

Glass Edge Deletion Machine

-

Vertical Glass Washing Machine

Vertical Glass Washing Machine