CNC Glass Cutting Machine

SCLM CNCGlass Cutting Machine

The SCLM CNC glass cutting machine consists of thefully automatic glass loading table, CNC glass cutting table and breakingtable. Adopting the CNC control system and AC servo motor drive, this machinecan automatically achieve optimum glass management and complete the loading,cutting and breaking of glass.

Technical features:

1) Our CNC glass cutting machinecan also make high-precision and high-speed linear and shaped cutting on theglass.

2) This CNC glass cutting machinecan achieve a cutting speed as high as 100m/min. When used for linear cutting, the total areaof glass processed by our CNC glass cutting capacity can reach 5000 sqm/ shift.

3) With the features of easy andautomatic operation, as well as stable and reliable performance, this CNC glasscutting machine has become one of the most important equipment for modernmedium and large enterprises in the glass processing industry.

4) The loading table of the CNCglass cutting machine adopts the imported vacuum pump used for the safe andefficient absorption of glass.

5) The X1, X2-axis of the cuttingtable features synchronous dual driveand adopts servo control system, which ensures even strength, strong power andsmooth operation.

6) The interlock function is alsoavailable to secure safety. The Y-axis cutting bridge adopts imported dualguide rail for stable and reliable operation.

7) The kinematic pair of the CNCglass cutting machine adopts the imported square guide rail and gear rack,which guarantees the accurate cutting effect and long service life.

8) This CNC glass cutting machineis also equipped with a laser positioning system to ensure precision andefficient glass positioning at all times.

Technical Parameters of the CNC Glass Cutting Machine

Cutting precision: ≤±0.30mm

Max. cutting size: 3660×2750 mm

Glass thickness: 3~19 mm

Cutting speed: 100 m/min

Working table height: 930±25 mm

Cutting table dimension: 4710×3250×930 mm

Cutting table weight: 1500 kg

Loading table transport speed: 40 m/min

Loading table tilting speed: 7 m/min

Loading table forward distance: 1000 mm

Loadingtable max. absorption size: 3660×2750mm

Loading table min. absorption size:1800×1800 mm

Loading table dimension(single-side, two-station): 6000×3900×930mm

Max. glass stack height: 800 mm

Min. glass nog height: 240 mm

Breaking table dimension: 4200×3000×930mm

Air cushion motor power: 5.5 kw

Air pressure: 0.5--0.8 Mpa

Power supply: AC380V, 50Hz

Total power: 18.5KW

Key Components of the CNC Glass Cutting Machine

| No. | Name | Brand |

| 1 | Rack | Taiwan YYC |

| 2 | Square guide rail | Taiwan HIWIN |

| 3 | Vacuum pump | Germany Becker |

| 4 | low-voltage electrical appliance | France Schneider |

| 5 | Hydraulic reversing servo valve | Germany Parker |

| 6 | Cutter | Germany Bohle |

| 7 | Reducer | Germany EISELE |

| 8 | Numerical control system | Japan YASKAWA |

| 9 | Servo motor | Japan YASKAWA |

| 10 | Photoelectric switches | Korea AUTONICS |

| 11 | Micro Switch | Japan Omron |

| 12 | Position switch | France Schneider |

| 13 | laser sensor | Switzerland BAUMER |

| 14 | Industrial computer | U.S. DELL |

DECA is a specialized CNC glass cutting machine manufacturer in China. We offera wide array of products including insulating glass production line, sealantspreading machine, auto sealing robot, glass loading machine, and much more.

Links:https://www.globefindpro.com/products/91639.html

-

ST02 Sealant Spreading Machine

ST02 Sealant Spreading Machine

-

ST02A Sealant Spreading Machine

ST02A Sealant Spreading Machine

-

Glass Edge Finishing Machine

Glass Edge Finishing Machine

-

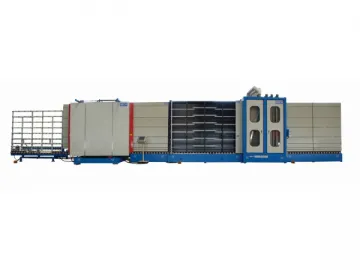

2500 Insulating Glass Production Line

2500 Insulating Glass Production Line

-

Hose Cleaning Machine

Hose Cleaning Machine

-

Hose Crimping Machine 81B

Hose Crimping Machine 81B

-

Glass Loading Machine

Glass Loading Machine

-

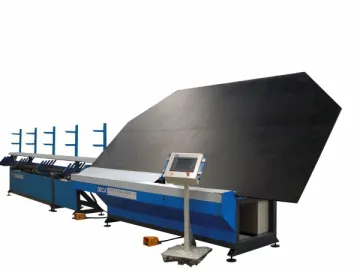

Automatic Spacer Bending Machine

Automatic Spacer Bending Machine

-

JT03 Butyl Extruder Machine

JT03 Butyl Extruder Machine

-

Horizontal Glass Washing Machine

Horizontal Glass Washing Machine

-

Automatic Desiccant Filling Machine

Automatic Desiccant Filling Machine

-

Gas Filling Machine

Gas Filling Machine