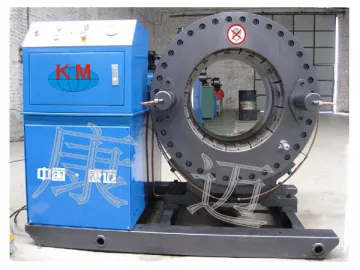

Hose Crimping Machine 92A

HoseCrimping Machine 92A

Model: KM-92A

Our hose crimpingmachine is equipped with imported components to give the machine a steady performance. The machine offers a large opening with diesand a good passing performance for elbow fitting. The hose crimpingmachine features two-grade speed and there is no axial displacement.

The hose crimping machine is equipped with a digital adjusting device ofcrimping in precise crimping amount. It is suitable for integrallyinstalling and uninstalling die.

Our hose crimpingmachine offers many special features including a compact and reliable crimping head.It is also designed with a wrong-die protection device, to prevent the machineto work when the die size is wrong. In addition, the operation system for thehose crimping machine is upgraded, which makes equipment operation convenientand user-friendly.

Technical Specifications of the HoseCrimping Machine

| Crimper range | 1/8" ~ 1 1/2" 4S H (hose I.D.) |

| Standard voltage & motor | 380V/4kw |

| Opening without dies | Φ 118 mm |

| Opening | ≥ 38mm |

| Swaging force | 2400 KN |

| Crimping Head Opening Time | ≤ 1.3s |

| Crimping Head Closing Time | ≤ 7.5 s |

| Optional voltage motor | Per customer’s requirement |

| No. of standard die set | 14 sets |

| Systematic pressure | 30Mpa |

| L*W*H | 690mm *465mm*7 28 mm |

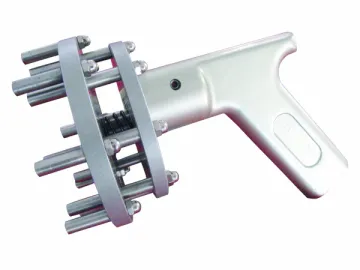

Hose Crimping Machine Accessories

Hose fixer(optional)

Die shelf

Die shelf

Die Chart for theHose Crimping Machine

| Die Bore (D) | Die Length (L) |

| 12mm | 56mm |

| 15mm | 56mm |

| 18mm | 56mm |

| 21mm | 56mm |

| 24mm | 100mm |

| 27mm | 100mm |

| 30mm | 100mm |

| 33mm | 100mm |

| 36mm | 100mm |

| 39mm | 100mm |

| 45mm | 100mm |

| 48mm | 100mm |

| 51mm | 100mm |

| 55mm | 100mm |

Maintenance shouldbe performed on a regular basis to keep the hose crimping machine in goodworking order. The work surface should be kept clean always. Before operating the machine, pick off the adapter (stage die) and add enough grease lubricant to the oil filler point on the die base andthe oil plug on the machine head. In order to extend the life of the hosecrimping machine, make sure the hydraulic oil is clean. At least twice a year,clean the mesh oil filter. Periodically check the bolts on the movementcomponent and pressed component. If they are loose, screw them down. When themachine is new, do not crimp a hose with a diameter above Φ38Ⅳ, wait about two to three months.

In order to meet your expectations and improve yourcomfort and efficiency, we can also offer special types of hose crimpingmachines. Our principle is based on technology, innovation and service toexpand the market.

As a professional hose crimping machinemanufacturer based in China,we provide a broad range of products that includes a hose cutting machine, hosecoupling inserter machine, hose skiving machine, and much more.

Links:https://www.globefindpro.com/products/91693.html

-

Hose Crimping Machine 91H

Hose Crimping Machine 91H

-

Hose Crimping Machine 91A

Hose Crimping Machine 91A

-

Hose Crimping Machine 91B

Hose Crimping Machine 91B

-

Hose Crimping Machine 91K

Hose Crimping Machine 91K

-

Hose Crimping Machine 92C

Hose Crimping Machine 92C

-

Hose Crimping Machine 91D

Hose Crimping Machine 91D

-

Hose Crimping Machine 91C

Hose Crimping Machine 91C

-

Hose Crimping Machine 92B

Hose Crimping Machine 92B

-

Hose Crimping Machine 81A

Hose Crimping Machine 81A

-

Hose Crimping Machine 91S

Hose Crimping Machine 91S

-

Hose Crimping Machine 81B

Hose Crimping Machine 81B

-

Hose Cleaning Machine

Hose Cleaning Machine