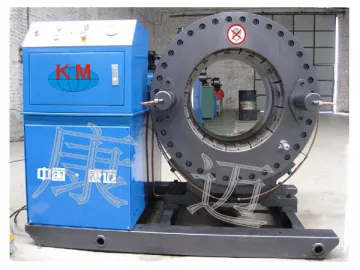

Hose Crimping Machine 92C

Hose Crimping Machine92C

Model: KM-92C

The hose crimping machine utilizes imported components to give the machine a steady performance. Offering a large opening with dies, it is suitable for crimping special elbow fitting. Equipped with a protection adapter to guard dies against the failure installation, the hose crimping machine also features a precise numerical regulator, in precision of 0.01mm. The dies of the machine can be changed integrally, quickly and easily.

In order to ensure user-friendly operation, the operation system for the hose crimping machine has been upgraded. Also, the machine The machine has a reliable and compact crimping head. When a wrong sized die is utilized, the hose crimping machine will automatically stop working. The machine body and the die shelf can be separated from each other.

Technical Specifications of the Hose Crimping Machine

Crimper range | 1/8" ~2 1/2 “/4” (hose I.D.) |

Standard voltage & motor | 380V/4kw |

Opening without dies | Φ 160mm |

Opening | ≥ 38mm |

Swaging force | 3400KN |

Open | ≤ 1.5 S |

Close | ≤ 8 S |

No. of standard die set | 16 dies |

Systematic pressure | 30Mpa |

Weight | 310Kg (including the die shelf : 40 Kg ) |

Noise level | ≤ 75dB |

L*W*H | 720mm *530mm*820mm |

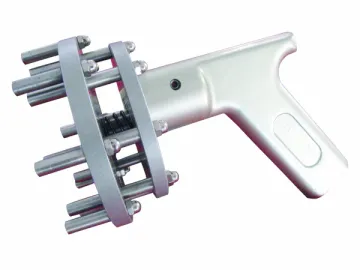

We offer accessories including optional hose fixer and die shelf.

Die Chart for the Hose Crimping Machine

Die Bore(D) | Die Length(L) |

12mm | 56mm |

15mm | 56mm |

18mm | 56mm |

21mm | 56mm |

24mm | 100mm |

27mm | 100mm |

30mm | 100mm |

33mm | 100mm |

36mm | 100mm |

39mm | 100mm |

45mm | 100mm |

48mm | 100mm |

51mm | 100mm |

55mm | 100mm |

63mm | 100mm |

67mm | 100mm |

73mm | 125mm (Option) |

Maintenance of the Hose Crimping Machine

To extend the service life and good working order of the hose crimping machine, we need to conduct regular maintenance. The work surface should be always clean, and before operating, pick off the adapter (stage die) and add enough grease lubricant to the oil filler point on the die base and the oil plug on the machine head. Clean hydraulic oil is a key to extend the lifespan of the hose crimping machine. The mesh oil filter should also be cleaned at least twice a year. Periodically inspect the bolts on the movement component and pressed component. Screw them down if they are loose. When the hose crimping machine is new, do not crimp a hose with a diameter above Φ38Ⅳ, wait about two to three months.

We are proud to offer special types of hose crimping machine to meet your expectations and improve your comfort and efficiency. Our principle is based on technology, innovation and service to expand the market.

Kangmai Hydraulic is a professional hose crimping machine manufacturer and supplier based in China. Our primary products include hose cutting machine, hose pressure test bench, hose skiving machine, and hose coupling inserter machine.

Links:https://www.globefindpro.com/products/91704.html

-

Hose Crimping Machine 91D

Hose Crimping Machine 91D

-

Hose Crimping Machine 91L

Hose Crimping Machine 91L

-

Hose Crimping Machine 92S

Hose Crimping Machine 92S

-

Ultrasonic Thickness Tester, TT360

Ultrasonic Thickness Tester, TT360

-

Coating Thickness Tester, TT290

Coating Thickness Tester, TT290

-

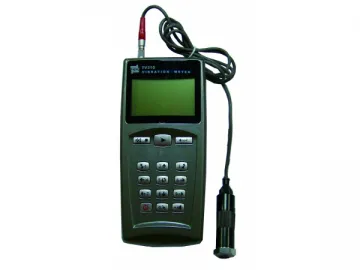

Vibration Tester, TV310

Vibration Tester, TV310

-

Hose Crimping Machine 91K

Hose Crimping Machine 91K

-

Hose Crimping Machine 91B

Hose Crimping Machine 91B

-

Hose Crimping Machine 91A

Hose Crimping Machine 91A

-

Hose Crimping Machine 91H

Hose Crimping Machine 91H

-

Hose Crimping Machine 92A

Hose Crimping Machine 92A

-

Hose Crimping Machine 91C

Hose Crimping Machine 91C