Coating Thickness Tester, TT270

Coating Thickness Tester, TT270

TT270 coating thickness tester is designed and manufacturedon the basis of current technologies and our years of experience in the field.Hence, it offers many great features as follows:

1. The coatingthickness tester provides two measuring modes: continuousand single.

2. It has two working modes, including direct mode (DITECT)and batch mode (APPL).

3. The thickness tester comes with backlight display, whichenables the user to see the test results clearly even in darkness.

4.Six types of probes are available for various applications, including F400, F1,F1/90, F10, N1, and CN02.

5. The coating thickness tester has low battery indication function andprovides five statistical values: Mean value, Max. value, Min. value, testing numbers.(No.), andstandard deviation (S.DeV).

6. 640 readings can be stored in the memory. The measured values can also beprinted out through an integrated printer.

7. Two measuring calibration modes, manual and auto shutoff modes are available.

Applicationsof TT270 Coating Thickness Tester

The coating thickness tester hastwo measuring methods: magnetic induction (F) and eddy current (N). When it is equipped withF probe, the coating thickness gauge can measure the non-magnetic coatings onmagnetic substrates, e.g., gold, copper, zinc, tin, lead, resin,rubber, glass coatings on the substrates of iron, steel, cobalt and nickel, andmore. When N probe is connected, the instrument canmeasure the non-conductive coating on non-magnetic substrates, e.g., synthetic resin, rubber, glass, paint coatings on the substrates of brass, copper,aluminum, and so on.

Technical Specifications of TT270 Coating Thickness Tester

| Measuring range | See table in the following |

| Probe available | |

| Tolerance | |

| Minimum resolution | |

| Measuring condition | |

| Operation language | English/Chinese |

| Standards | DIN,ISO,ASTM,BS |

| Calibration | Zero and foil calibration |

| Interface | RS232 |

| Statistic | Number of measurement, mean value, standard deviation, maximum value and minimum value |

| Data memory | 640 readings |

| Limits | Adjustable with alarm |

| Power supply | NiMH rechargeable battery |

| Dimensions(mm) | 230×86×47 |

| Operating environment | Temperature:0~40 |

| Humidity:20%~90% | |

| No strong magnetic field |

Optional Probes and Application Guide

| Probe model | F400 | F1 | F1/90 º | F10 | N1 | CN02 | |||

| Operating principle | Magnetic induction | Eddy current | |||||||

| Measuring range (µm) | 0-400 | 0-1250 | 0-10000 | 0 to 1250 μm 0 to 40 μm (for chromeplate on copper) | 10~200 | ||||

| Low range resolution (µm) | 0.1 | 0.1 | 10 | 0.1 | 1 | ||||

| Accuracy | One-point calibration (µm) | ±(3%H 1) | ±(3%H 10) | ±(3%H 1.5) | ±(3%H 1) | ||||

| Two-point calibration (µm) | ±[(1~3)H% 0.7] | ±[(1~3)H% 1] | ±[(1~3)%H 10] | ±[(1~3)%H 1.5] | - | ||||

| Measuring conditions | Min curvature of the min area (mm) | Convex | 1 | 1.5 | Flatten | 10 | 3 | Flatten | |

| Diameter of the min area (mm) | φ3 | φ 7 | φ7 | φ40 | φ 5 | φ7 | |||

| Critical thickness of substrate (mm) | 0.2 | 0.5 | 0.5 | 2 | 0.3 | unlimited | |||

Reference Table for ProbeSelection

| Substrates | Non-magnetic coatings (Organic materials) | Non-magnetic coatings(nonferrous metals) | ||||

| Thickness of coatings is more than 100 | ||||||

| Steel, iron and other magnetic metal | Diameter of testing area is more than 30mm | F1 probe:0~1250 µm F400 probe:0~400µm | F1 probe:0~1250 µm F10 probe:0~10µm | F400 probe:0~400 µm F1 probe:0~1250µm | F1 probe:0~1250 µm F10 probe:0~10µm | |

| Diameter of testing area is less than 30mm | F400 probe:0~400µm | F1 probe:0~1250 µm F400 probe:0~400µm | F400 probe:0~400µm | F400 probe:0~400 µm F1 probe:0~1250µm | ||

| Copper, brass, aluminum, zinc, tin and other metallic substrate | Diameter of testing area is more than 5mm | N1 probe:0~1250µm | N1 probe:0~40µm (For chromeplate on copper) | |||

| Plastic nonmetallic substrate | Diameter of testing area is more than 7mm | - | - | CN02 Probe:10~200µm | ||

Standarddelivery for our coating thickness tester includes main unit, probe, substrate,calibration foil, charger, printing paper, instruction manual, TIME certificate and warranty card.

Asa China based coating thickness tester manufacturer, we provide a comprehensive rangeof products that includes ultrasonic flaw detector, surface roughness tester,X-ray generator, portable hardness tester, and much more.

Links:https://www.globefindpro.com/products/91760.html

-

Compact Laminate Locker L138

Compact Laminate Locker L138

-

Coating Thickness Tester, TT211

Coating Thickness Tester, TT211

-

Ultrasonic Flaw Detector, TUD500

Ultrasonic Flaw Detector, TUD500

-

Vickers Hardness Tester, TH722

Vickers Hardness Tester, TH722

-

Ultrasonic Thickness Tester, TT100

Ultrasonic Thickness Tester, TT100

-

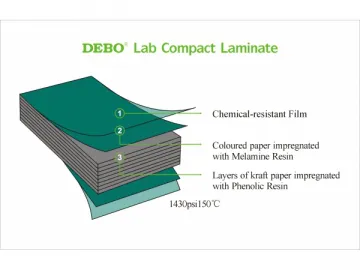

Lab Compact Laminate

Lab Compact Laminate

-

Vickers Hardness Tester, TH720

Vickers Hardness Tester, TH720

-

Coating Thickness Tester, TT230

Coating Thickness Tester, TT230

-

Brinell Hardness Tester

Brinell Hardness Tester

-

G Type Portable Hardness Tester

G Type Portable Hardness Tester

-

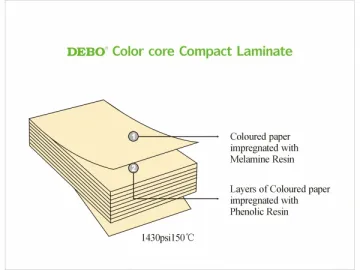

Color Core Compact Laminate

Color Core Compact Laminate

-

Compact Laminate Locker L126

Compact Laminate Locker L126