Integrated Portable Hardness Tester

Integrated PortableHardness Tester

Our integrated portable hardness tester is a newhardness testing machine that offers high precision, small size and easyoperation. This hardness tester has many great functions, such as integratedcalibration, upper and lower limit setting, automatic switching off, batterycapacity display and automatic identification of impact test direction. In addition, theinstrument is designed with backlight for convenient use in darkness. Theportable hardness tester also has USB communication interface and can store 270average readings in 9 group files.

Ourintegrated portable hardness tester comes in three models, including TH170,TH172 and TH174. The TH170portable hardness tester isintegrated with D impact device for normal hardness testing. The TH172 hardnesstesting instrument is integrated with C impact device for hardness testing onthin, light and face hardened workpieces. TheTH174 hardness testing equipment is integrated with DL impact device forhardness testing of deep grooves and tooth surface.

Usually, ourintegrated portable hardness testers are used for hardness tests on installedmachinery and permanently assembled parts, heavy and large workpieces, axletree and other spareparts. They are also suitable for workpieces with narrow test space, like mould cavity. Inaddition, our portable hardness testers can be used for material identificationapplication in metal material warehouse and failure analysis of pressurevessel, steam turboset and other equipment.

Technical Specifications of Integrated Portable HardnessTester

| Model | TH170 | TH172 | TH174 |

| Impact device | D integrated | C integrated | DL integrated |

| Hardness scales | HLD, HB, HRC, HRB, HV, HS | HLC, HB, HRB, HRC, HV, HS | HLDL, HB, HRC, HRB, HV, HS |

| Accuracy | ±6HLD(760 ±30HLD) | ±12HLC | ±12HLDL |

| Memory | 270 average readings in 9 groups | ||

| Output interface | USB 2.0 to computer | ||

| Average surface roughness of workpiece | 1.6μm(Ra) | 0.4μm (Ra) | 1.6μm(Ra) Diameter = 2.8mm |

| Max. workpiece hardness | 900HLD | 960HLC | 950HLDL |

| Min. radius of workpiece (convex/concave) | Rmin = 50mm (with support ring Rmin= 10mm) | Rmin = 11mm (with support rings ) | Rmin = 10mm |

| Min. workpiece weight | 2~5kg on stable support 0.05~2kg with compact coupling | 0.5~1.5kg on stable support 0.02~0.5kg with compact coupling | 2~5kg on stable support 0.05~2kg with compact coupling |

| Min. thickness of workpiece coupled | 5mm | 1mm | 5mm |

| Min. thickness of hardened layers | 0.8mm | 0.2mm | 0.8mm |

| Continuous working time | 150 h(without backlight) | 150 h(without backlight) | 150 h(without backlight) |

| Power | AAA 1.5V batteries (2PCS) | ||

| Operating temperature | 0~40℃ | 0~40℃ | 0~40℃ |

| Overall dimensions(mm) | 155×55×25 | 160×60×25 | 215×60×25 |

| Weight(g) | 166 | 180 | 180 |

Standard delivery for our integrated portable hardness tester includes main unit,test block with HLD value, USB connecting cable, cleaning brush, two AAA 1.5Vbatteries, as well as TIME certificate, instruction manual, warranty card andcarrying case. Optional accessories such as support rings are also available.

As an integrated portable hardness tester manufacturer and supplier in China, we alsoprovide surface roughness tester, X-ray generator, Brinell hardness tester, ultrasonic flaw detector,and much more.

Links:https://www.globefindpro.com/products/91774.html

-

Ultrasonic Flaw Detector, TUD310

Ultrasonic Flaw Detector, TUD310

-

Portable Hardness Tester

Portable Hardness Tester

-

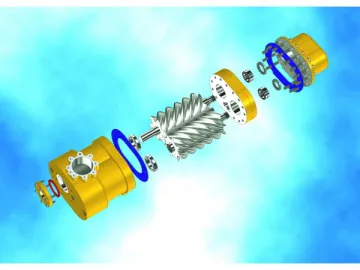

Stationary Screw Air Compressor Parts

Stationary Screw Air Compressor Parts

-

VSD Screw Air Compressor Parts

VSD Screw Air Compressor Parts

-

Stamping Parts for Washing Machine Back Plate

Stamping Parts for Washing Machine Back Plate

-

VSD Screw Air Compressor

VSD Screw Air Compressor

-

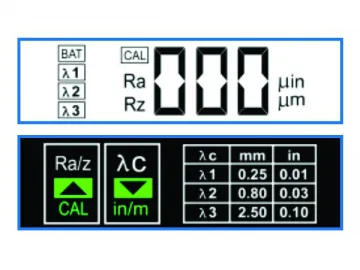

Surface Roughness Tester, TR100

Surface Roughness Tester, TR100

-

Vickers Hardness Tester, TH714

Vickers Hardness Tester, TH714

-

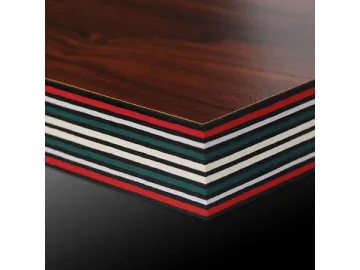

Multi Color Core Compact Laminate

Multi Color Core Compact Laminate

-

Vickers Hardness Tester, TH710

Vickers Hardness Tester, TH710

-

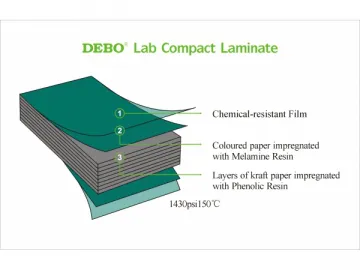

Lab Compact Laminate

Lab Compact Laminate

-

Ultrasonic Thickness Tester, TT100

Ultrasonic Thickness Tester, TT100