Progressive Die

Progressive Die

Product name: progressive die, progressive mould,progressive tool, progressive stamping die

Progressive die provides multiple working stations where successive operationsare performed in each punching stroke. After a stroke, the feeding system willmove the materials forward by a fixed distance. As akind of multi-tasking stamping dies, our progressive die enables multipleoperations including blanking, bending, drawing, and more, which results inhigh production efficiency. In addition to offering operational safety andautomation, the progressive die is suitable for high speed punching machine.The continuous production flow from material, through semi-finished product tofinal product, saves the trouble and expenses on transportation and warehousingof semi-finished products.

We use SKH-9, CR12MOV,SKD61, SKD11, P20 S etc. as material for the progressive die.The progressive mold comes in single-cavity and multi-cavity types. Withprecision of 0.02mm, theprogressive tool has life of up to 50000~500000 shots. The progressivedie uses PUNCH, MISUMI, DANLY and other makes of parts including Danly system, Fibro guide post,and Festo cylinder, etc.The progressive die is suitable for producing metal parts with such materialsas SUS304, 1.4301, AISI301, CS4, SPCC, DC01, AL, Copper, and others. Designedfor mass production of complicatedly shaped small parts, the progressivestamping die provides high cost performance, low energy consumption, and longuse life.

Our progressive dies are exported to many countries such as Japan, Italy,Iran, Egypt, and Argentina, to name a few. The metalstamping dies has applications in the fields of home appliances, auto parts,and electronic products, among others.

We usually quote the progressive die cost according to the product drawing orsample from customer. The basic essential information which need customer tooffer and what we can supply is indicated in the following table, for yourreference.

| Step | Item | Description |

| 1 | Quotation | We offer you the stamping die and part quotation according to your details (drawing or sample, material, quantity, weight). |

| 2 | Order | If our quotation is competitive, you will place the order. |

| 3 | Drawing design | We design the mould structure drawing according to your product drawing or sample, and then send to you for confirmation. |

| 4 | Mould making | After your confirmation of our drawing, we begin to make the moulds. During manufacture, we send you mould making progress with pictures every week, so you know our process. |

| 5 | First trial | We will make the stamping die and first trial on time, and then send you video, picture and 2~5 pcs of samples for you to confirm. |

| 6 | Quality confirmation | You will confirm our stamping die quality according to sample. If you need to adjust the product structure, we can help you to change it further. |

| 7 | Delivery | Ship the stamping die after it is completely OK, and the product is packed by wooden case. |

ISO9001:2008 certified, we accept the following filetypes of inquiry: Pro/E, Solidworks,UG, AutoCAD, Adobe, Acrobat, .dxf,.pdf, .x_t, .stp, .igs, .prt.

Links:https://www.globefindpro.com/products/91835.html

-

Stamping Parts for Washing Machine Back Flange

Stamping Parts for Washing Machine Back Flange

-

Threaded Pipe Joint

Threaded Pipe Joint

-

Pipe Fittings Threaded Plug

Pipe Fittings Threaded Plug

-

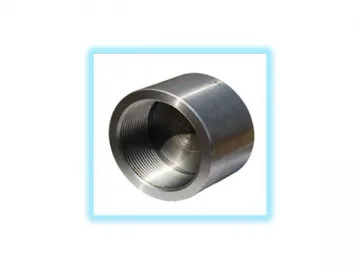

Pipe Fittings Socket Coupling

Pipe Fittings Socket Coupling

-

Pipe Fittings Steel Bend

Pipe Fittings Steel Bend

-

Socket Steel Tee

Socket Steel Tee

-

Stamping Metal Parts of Air Conditioner Bracket

Stamping Metal Parts of Air Conditioner Bracket

-

Stamping Air Conditioner Parts

Stamping Air Conditioner Parts

-

Threaded Pipe Tee

Threaded Pipe Tee

-

Threaded Pipe Cross

Threaded Pipe Cross

-

Pipe Fittings Threaded Cap

Pipe Fittings Threaded Cap

-

Refrigerator Stamped Parts

Refrigerator Stamped Parts