Lap Joint Pipe Flange

Lap Joint Pipe Flange

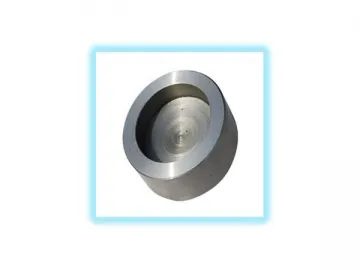

The lap joint flanges are used on piping fittedwith lapped pipe or with lap joint stub end. The lap joint flange with the stubend assembly is normally used in systems requiring frequent dismantling forinspection and cleaning. The ability to swivel flanges and to align bolt holeseases formation of large diameter or unusual stiff piping. The lap joint flangeis also used in applications where there is a need to facilitate boltalignment.

The lapjoint pipe flange can move on the pipe and is usually attached to water supplyand drainage accessories. It presses the flange and the steel ring which servesas sealing surface and is not exposed transferring the pressureto the gasket. The lap joint pipe flange is usually found in electricity, oiland gas, petrochemical, chemistry, paper making, metallurgical and otherindustries.

The process to manufacture a lap joint pipe flange is mold forged followed bymachine finished. There are two kinds of lap joint pipe flange,butt welding and flat welding.

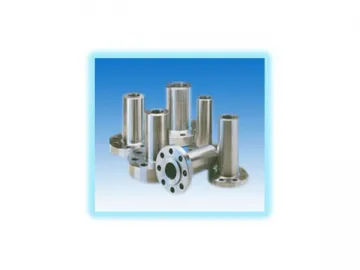

1. Butt Welding Lap Joint Pipe Flange

Butt welding lap joint flange’s out diameter is ranging from 3/8" to48" and its nominal diameter from DN10 toDN1200. Our company provides lapjoint flanges to work under pressure in accordance with American standard suchas CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500 and Europeanstandard such as PN 2.5, PN 6, PN 10, PN 16, PN 25 and PN 40. We also provide different flange faces in accordance with American standardfor raised face, tongue, groove, female, male and ring joint. European standardfor raised face, tongue, groove, female, male and ring joint are alsoavailable.

Raw Materials

Materials to produce butt welding lap joint pipe flanges are detailed here.

Carbon Steel: A105

Alloy Steel: A182 F 1-F 2-F 5-F 9-F 10-F 91-F 92-F 122-F 911-F 11-F 12-F 21-F22

Stainless Steel: A182 304-304H-304L-304N-304LN 316-316H-316L-316N-316LN321-321H 347-347H

Low Temperature Steel: A522 A707 Grade L 1-L 2-L 3-L 4-L 5-L 6-L 7-L8

High Performance Steel: A694 F 42-F 46-F 48-F 50-F 52-F 56-F 60-F 65-F 70

Standard Available

Our company provides butt welding lap joint pipe flanges of different standardsas follows.

GB/T9112-2000

GB/T9118.1-2000 GB/T9118.2-2000

GB/T9120.1-2000 GB/T9120.2-2000 GB/T9120.3-2000

GB/T9122-2000

GB/T9124-2000

SH/T3406-1996

JB/T74-1994

JB/T75-1994

JB/T84-1994

JB/T85-1994

HG/T20592-2009 HG/T20614-2009

HG/T20615-2009 HG/T20623-2009 HG/T20635-2009

ASME B16.5-2009

EN1092-1-2007 EN1759-1-2004

BS1560-3.1-1989 BS4504-3.1-1989

AFNOR NF E29-200-1-2007

ISO7005-1-1992

JIS B2220-2004

2. Flat Welding LapJoint Pipe Flange

The flat welding lap joint pipe flange out diametercan be from 3/8" to 24" and its nominal diameter from DN10 to DN600.Cangzhou Electricity Pipe-Fittings provides flat lap joint flanges operatingunder pressure in accordance with American standard for CLASS 150, CLASS 300,CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500 and the Europeanstandard for PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40.Our company also provides flat lap joint flanges of different flange faces inaccordance with American standard for raised face,tongue, groove, female, male and European standard for raised face, tongue,groove, female and male.

Raw Materials

Materials to produce flat welding lap joint pipe flanges are detailed here.

Carbon Steel: A105

Alloy Steel: A182 F 1-F 2-F 5-F 9-F 10-F 91-F 92-F 122-F 911-F 11-F 12-F 21-F22

Stainless Steel: A182 304-304H-304L-304N-304LN 316-316H-316L-316N-316LN321-321H 347-347H

Low Temperature Steel: A522 A707 Grade L 1-L 2-L 3-L 4-L 5-L 6-L 7-L 8

High Performance Steel: A694 F 42-F 46-F 48-F 50-F 52-F 56-F 60-F 65-F 70

Standard Available

Our company provides flat welding lap joint pipe flanges of differentstandards as follows.

GB/T9112-2000

GB/T9121.1-2000 GB/T9121.2-2000 GB/T9121.3-2000

GB/T9124-2000

SH/T3406-1996

JB/T74-1994

JB/T75-1994

JB/T83-1994

HG/T20592-2009 HG/T20614-2009

HG/T20615-2009 HG/T20623-2009 HG/T20635-2009

ASME B16.5-2009

EN1092-1-2007 EN1759-1-2004

BS1560-3.1-1989 BS4504-3.1-1989

AFNOR NF E29-200-1-2007

ISO7005-1-1992

JIS B2220-2004

Links:https://www.globefindpro.com/products/91862.html