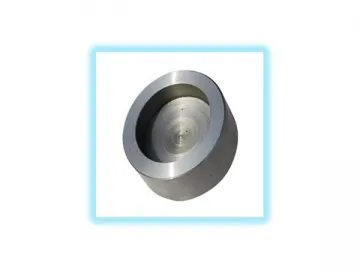

Pipe Fittings Socket Cap

Pipe Fittings Socket Cap

The pipe fitting socketcap is connected to pipe end in high pressure pipeline systems by means ofscrew or welding connection. It is suitable to avoid leaking. According todifferent cap shapes, pipe fittings socket cap can be categorized as convexsocket cap, conical shell socket cap, reducer socket cap, flat socket cap andtight inlet socket cap. In order to meet requirements ofanti-corrosion and high pressure applications, pipe fitting socket cap uses advancedmanufacturing technology by mold forged and machining process.

Thedirection of welding seam can only be radial or circular. Besides, heataffected zone is strictly controlled, every product is radiographic andultrasonic tested to make sure that every pipe fitting socket cap has highquality. Its wall thickness ranges from 1/8" to 4" and its nominal diameterfrom DN6 to DN100. Our company provides under pressure pipe fittingsocket cap for American standards with CLASS 3000, CLASS 6000and CLASS 9000 series.

Raw Materials

Materialsused to produce the pipe fitting socket cap are listed here.

Carbon Steel: A105

Alloy Steel: A182 F 1-F 2-F 5-F 9-F 10-F 91-F 92-F 122-F 911-F 11-F 12-F 21-F22

Stainless Steel: A182 304-304H-304L-304N-304LN 316-316H-316L-316N-316LN 321-321H347-347H

Low Temperature Steel: A522 A707 Grade L 1-L 2-L 3-L 4-L 5-L 6-L 7-L 8

High Performance Steel: A694 F 42-F 46-F 48-F 50-F 52-F 56-F 60-F 65-F 70

Standard Available

Standards for our pipe fitting socket capare the following:

GB/T14383-2008

SH/T3410-1996

HG/T21634-1988

ASME B16.11-2005

BS3799-1974

JIS B2316-2007

Links:https://www.globefindpro.com/products/91865.html