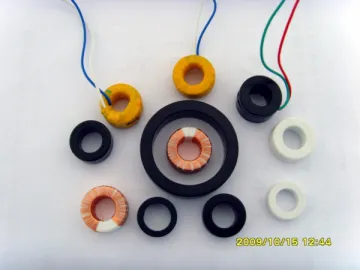

Tape Wound Core for Current Transformer

Tape Wound Core for Current Transformer

The tape wound core forcurrent transformer offers high permeability,which provides greatly improved transformer precision, and can reduce ratioerror as well as angle error. It is lightweight and cost effective, significantlylower in price than current transformer cores made of permalloy. Thetape wound core for current transformer features excellent temperaturestability and can work at -55 - 130 ℃for long hours. The saturation magnetic flux density between silicon steel and permalloyis conducive to reducing the instrument security factor.

The tape wound core for current transformer can be used as measuringcurrent transformer substation core, with the accuracy of 0.5-0.01 grade, andrated voltage from 0.5kv to 500kv.

Current transformers are designed to measure current on transmission lines.According to measurement precision requirements, the cores for currenttransformer can be made of different soft magneticmaterials. The higher the current transformer core’s permeability is, thehigher the measurement precision will be. At present, the most widely used corematerials are cold-rolled silicon steel, permalloy and nanocrystalline alloy.

In recent years, the demand for high-precision level current transformers, such as the 0.2, 0.2S level, 0.5S level, isincreasing rapidly. When a lower transformation ratio or less ampere-turn isrequired, or the size of core is restricted by the size of the transformer,cores made of cold-rolled silicon steel will not meet the precisionrequirements. Although permalloycores with high permeability can achieve the required precision, its price istoo high. By using tape wound core for current transformer, precisionrequirements will be met, and the price is also lower than permalloy cores.

Physical Property of Tape Wound Core For Current Transformer

| Material | Resistivity (Ω µ.cm) | Curie Temperature (Tc) | Saturated Induction Density Bs(T) | Saturated Magnetostrictive Coefficient (λ s) | Occupation Efficiency (%) |

| HX-NC | 130 | 570 | 1.25 | 2.7*10 -6 | ~78 |

Dimensionsof Tape Wound Core for Current Transformer

| External Diameter(D) | Inside Diameter (d) | Height (H) |

| 10~500mm | 5~450mm | 3.0~80mm |

Other specificationsmay be ordered according to the requirements of the client.

The specification and performance of tape wound core for current transformer for mutual inductorunder testing conditions f=50 KHz, N1=N2=1 of V-A testing

| ID/OD*H | Input Current (mA) | Output Voltage (mV) |

| Φ14/19*6.5 | 50 | 1.50 |

| Φ13.2/21.5*10 | 50 | 4.50 |

| Φ16/26*10 | 50 | 4.50 |

| Φ18/28*15 | 100 | 9.00 |

| Φ40/50*10 | 100 | 2.50 |

| Φ90/130*25 | 140 | 55.00 |

| Φ90/130*50 | 140 | 110.00 |

| Φ85/125*20 | 480 | 45.00 |

| Φ85/125*30 | 480 | 67.00 |

| Φ200/260*20 | 500 | 15.50 |

| Φ280/485*20 | 200 | 4.20 |

| Φ510/590*35 | 598 | 12.00 |

Other specifications may beordered.

As a China-based manufacturer of tape wound core for current transformer, ourcompany also offers high power transformer iron core, iron based amorphousstrip, amorphous C core, split-core current transformer, and much more.

Links:https://www.globefindpro.com/products/92179.html

-

Electric Potential Transformer

Electric Potential Transformer

-

Aluminium Mirror

Aluminium Mirror

-

Micro Current Transformer

Micro Current Transformer

-

Zero Phase Current Transformer

Zero Phase Current Transformer

-

Current Transformer with DC Immune

Current Transformer with DC Immune

-

Switch Tape Wound Core

Switch Tape Wound Core

-

Silver Mirror

Silver Mirror

-

Iron Based Nanocrystalline Strip

Iron Based Nanocrystalline Strip

-

Common Mode Inductor Iron Core

Common Mode Inductor Iron Core

-

Ultra Clear Float Glass

Ultra Clear Float Glass

-

R134a Refrigeration Compressor 195W

R134a Refrigeration Compressor 195W

-

Tinted Float Glass

Tinted Float Glass