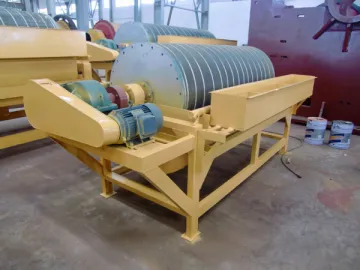

Wet Magnetic Separator

Wet Magnetic Separator

The magnetic system of our wet magnetic separator is aring-shape chain closed magnetic circuit with energizing coils which are made of copper tube and cooled internally by water. Grooved platesmade of magnetic conductive stainless steel are used as magnetic matrix. Ourwet magnetic separator features short magnetic circuit, little magnetic fluxleakage, high magnetic intensity, low energy consumption, fine beneficiatingresults, simple structure and is easy to maintain.

Working Principle of Wet MagneticSeparator

When slurry flows into trough across ore feedingtank, loose ore particles enter then trough's ore-feeding zone under waterflowof ore feeding hosepipe. Because of the magnetic field effect, magneticparticles get together and form into magnetic mass or magnetic linkage, which isabsorbed on the cylinder under magnetic force when it moves toward the magneticpole. As the polarity of magnetic pole is alternately disposed along thecylinder's rotation direction and remains unchanged at work, gangueand other non-magnetic minerals among magnetic mass or magnetic linkage falloff when the cylinder rotates. The magnetic mass or magnetic linkage that is still absorbed on the cylinder surface comes out as oreconcentrate. Then whenit moves to the marginal magnetic system with lowestmagnetic force along the cylinder rotation, the oreconcentrate is unloaded into concentrate trough under waterflow of ore-unloadinghosepipe. Non-magnetic or weak magnetic minerals left in the slurry aredischarged out of trough, which are called ore tailings.

Applications

Ourmagnetic separator is suitable for wet magnetic separation of materials lessthan 3mm such asmagnetite, calcined ore, etc. and it can remove the iron in the coal, non-metaland in construction industries.

Main Technical Parameters of our Wet Magnetic Separator

| Model | Dia. of Cylinder (mm) | Length of Cylinder (mm) | Rotary Speed of Cylinder (mm) | Feeding Size (mm) | Capacity (t/h) | Power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| Basic Data | Model | |||||

| GYC-60B | GYC-60B-I | GYC-2*60 | GYC-3*60 | GYC-3*80 | GYC-4*80 | |

| Cylinder Diameter*Length (mm) | ø320*600 | ø320*600 | ø320*600 | ø320*600 | ø404*800 | ø404*800 |

| Max. Magnetic Induction | 3500 | 1100 | 3500 | 110-3000-3500 | 110-3000-3500 | 110-3000-5000 |

| Cylinder Quantity | 1 | 1 | 2 | 3 | 3 | 4 |

| Cylinder Rotation Speed (r/min) | 66.47.33 | 66.47.33 | 66.47.33 | 34.5-172 | 54.5-172 | 54.5-172 |

| Sorting Size (mm) | 0.05-25 | 0.063-25 | 0.05-25 | 0-8 | 0-8 | 0-8 |

| Motor Model | Y801-4 | Y801-4 | Y801-4 | ZBW-1.5 | ZBW-1.5 | ZBW-1.5 |

| Power (kw) | 0.75 | 0.75 | 0.75 | 1.1 | 1.5 | 2.2 |

| Productivity (t/h) | 0.5-2.5 | 0.1-3 | 0.5-2.5 | 0.8-2.5 | 1.5-2.5 | 1.5-2.5 |

| Weight (t) | 0.25 | 0.65 | 0.5 | 1.2 | 1.5 | 2.4 |

| Remark | Fine selection | Coarse selection | Fine selection | With vibrating feeder | With vibrating feeder | Fine selection |

The main machinery is in nude packing and spares partsare packed in wooden or steel box. The standard export packing is suitable for longdistance delivery.

As one of the largest Chinese professional wet magneticseparator manufacturers and suppliers, ZhengzhouHongji provides high quality and large capacity of products to ourcustomers at lower price.

Links:https://www.globefindpro.com/products/92916.html