Ore Dressing Ball Mill

Ore DressingBall Mill

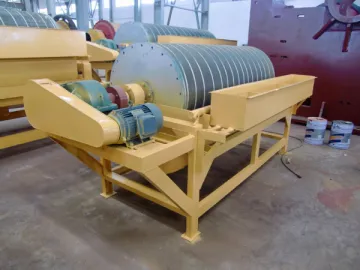

The ore dressing ball mill is applied forgrinding of various ores or other material. In addition,it is widely used in mining, construction and chemical industries with wetgrinding and dry grinding methods.

Structure

Ourore dressing ball mill is composed of feeding part,discharging part, turning part and driving part (reducer, small driving gear,electric motor and electric control). The quillshaft of this ball mill adopts cast steel part and the liner isdetachable. The turning gearwheel adopts casting hobbingprocess and the drum is equipped with wear-resistant liner, which has goodwear-resistance.

Features

1.Compared with traditionalball mill, the ore dressing ball mill fan saves power from 18 to 25%, lubrication of 70% and cooling water of 90%, and comprehensivelysave energy above 20%.

2. It does not need to change the main shaft in 10 years, which willsave much maintenance fee and labor hours. Main shaft lubrication uses grease,which is convenient, clean and prevents heavy metal pollution.

3. The main shaft adopts double row self aligning roller bearing.

4. Ourore dressing ball mill offers an integrateddesign of the body and base, which facilitates installation.

5. It has stableand reliable working condition.

Working Principle

Our oredressing ball mill is a horizontal cylindricaldevice with two chambers. The material is evenly sent to the firstchamber via quill shaft. This chamber has many steel balls in differentspecifications. Under the centrifugal force of the rotating cylindrical device,these balls are thrown high and then fall back on thematerial to be ground. After being primarily crushed in the first chamber, thematerial passes through the single layer diaphragm plate and enters the secondchamber, where it is further ground by steel balls. Finally, the powderymaterial is discharged through the grate plate.

MainTechnical Parameters of OreDressing Ball Mill

| Model | Rotation Speed (r/min) | Ball Load (t) | Feeding Size (mm) | Discharging Size (mm) | Capacity (t/h) | Power (kw) | Weight (t) |

| Ø900*2100 | 36-38 | 1.5 | 0-15 | 0.075-0.8 | 0.5-1.3 | 18.5 | 4.9 |

| Ø120*2800 | 36 | 3.5 | 0-20 | 0.075-0.8 | 1.2-3.7 | 37 | 12.5 |

| Ø1500*3500 | 29.7 | 7.5 | 0-25 | 0.075-0.8 | 3.3-8.8 | 75 | 16.5 |

| Ø1830*3600 | 25.4 | 13 | 0-25 | 0.075-0.8 | 4-8 | 130 | 30 |

| Ø2100*3600 | 23.7 | 18 | 0-25 | 0.075-0.8 | 4.5-33 | 180 | 37 |

| Ø2400*3000 | 21 | 23 | 0-25 | 0.075-0.8 | 7-50 | 245 | 54 |

| Ø2700*3600 | 20.7 | 40 | 0-25 | 0.075-0.8 | 12-75 | 400 | 86 |

The main machinery is in nude packing and spares partsare packed in wooden or steel box. The standard export packing is suitable for longdistance delivery.

As one of the largest Chinese professional ore dressing ball mill manufacturers and suppliers, Zhengzhou Hongji provideshigh quality and large capacity of products to our customers at lower price.

Links:https://www.globefindpro.com/products/92921.html