Ball Mill

Ball Mill

Ball mill is an important piece of grinding equipment after the crushingprocess, and it is widely used in many industries, such as cement,silicate, new building material, refractory material, fertilizer, ferrousmetal, nonferrous metal, and glass ceramics. The ball mill can be used for drying and wetgrinding of nearly all kinds of ores and othergrindable materials. Typically, this product is found in ore beneficiation process and aeratedconcrete plant.

Structure of Our Ball Mill

Our ball mill is mainly composed of feeding section, dischargingsection, rotating section, driving section (reducer, pinion, motor, electriccontrol), etc. The quill shaft is made of carbon steel, with replaceable inner lining. Our rotary gearwheel is processedwith gear hobbing and wearable lining plate in the shell to guarantee nice wearresistance. The ball mill machine runsstably in available working status.

Main Technical Parametersof Ball Mill

| Model | Shell Rotation Speed (r/min) | Ball Load (t) | Feeding Size (mm) | Discharging Size (mm) | Capacity (t/h) | Power (kw) | Weight (t) |

| ø900*1800 | 36-38 | 1.5 | <=20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| ø900*3000 | 36 | 2.7 | <=20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| ø1200*2400 | 36 | 3 | <=25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| ø1200*3000 | 36 | 3.5 | <=25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| ø1200*4500 | 32.4 | 5 | <=25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| ø1500*3000 | 29.7 | 7.5 | <=25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| ø1500*4500 | 27 | 11 | <=25 | 0.074-0.4 | 3-6 | 90 | 21 |

| ø1500*5700 | 28 | 12 | <=25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| ø1830*3000 | 25.4 | 11 | <=25 | 0.074-0.4 | 4-10 | 130 | 28 |

| ø1830*4500 | 25.4 | 15 | <=25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| ø1830*6400 | 24.1 | 21 | <=25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

| ø1830*7000 | 24.1 | 23 | <=25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

| ø2100*3000 | 23.7 | 15 | <=25 | 0.074-0.4 | 6.5-36 | 210 | 34 |

| ø2100*4500 | 23.7 | 24 | <=25 | 0.074-0.4 | 8-43 | 245 | 42 |

| ø2100*7000 | 23.7 | 26 | <=25 | 0.074-0.4 | 8-48 | 280 | 50 |

| ø2200*4500 | 21.5 | 27 | <=25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| ø2200*6500 | 21.7 | 35 | <=25 | 0.074-0.4 | 14-26 | 370 | 52.8 |

| ø2200*7000 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-28 | 380 | 54 |

| ø2200*7500 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-30 | 380 | 56 |

| ø2400*4500 | 21 | 30 | <=25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| ø2700*4000 | 20.7 | 40 | <=25 | 0.074-0.4 | 12-80 | 400 | 94 |

| ø2700*4500 | 20.7 | 48 | <=25 | 0.074-0.4 | 12-90 | 430 | 102 |

| ø3200×3600 | 20.2 | 52 | ≤25 | 0.074-0.4 | 12-75 | 400 | 86 |

| ø3200*4500 | 18 | 65 | <=25 | 0.074-0.4 | 25-130 | 800 | 137 |

The main machinery is in nude packing andspares parts are packed in wooden or steel box. The standard exportpacking is suitable for long distance delivery.

As one of the largest Chinese professional ball millmanufacturers and suppliers, Zhengzhou Hongji provides high qualityand large capacity of products to our customers at lower price.

Links:https://www.globefindpro.com/products/92931.html

-

Paper Handle Making Machine

Paper Handle Making Machine

-

Paper Cup Forming Machine

Paper Cup Forming Machine

-

Gravure Printing Machine

Gravure Printing Machine

-

Creasing and Die Cutting Machine

Creasing and Die Cutting Machine

-

Hot Melt Coating Machine

Hot Melt Coating Machine

-

Paper Rope Making Machine

Paper Rope Making Machine

-

PE Laminating Machine, Coating Machine

PE Laminating Machine, Coating Machine

-

Speed Gravure Printing Machine

Speed Gravure Printing Machine

-

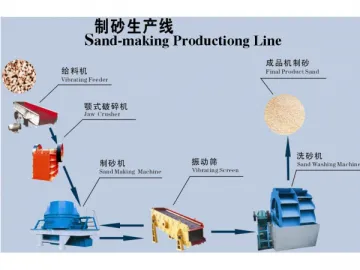

Sand Making Production Line

Sand Making Production Line

-

Dry Magnetic Separator

Dry Magnetic Separator

-

Stone Sand Production Line

Stone Sand Production Line

-

Limestone Ball Mill

Limestone Ball Mill