Plastic Bag Making Machine, FQ-B

Plastic Bag MakingMachine

The plastic bag making is used for theheat-sealing and thermal cutting of such plastic films as LDPE and HDPE, etc. It is the typeof equipment used for specially producing vest bags of natural color andmulticolor.

Features of Plastic Bag MakingMachine

1. The plastic bag making machine offers a thermalcutting device with a new style design, easy and fast pressure adjustment ofsealing and cutting knife, 180 integral turnover, and easy clearing andreplacing of glue cloth.

2. It offers imported reflecting photoelectricswitch monitoring, stable and reliable feeding, and automatically stops themachine when the color mark is lost.

3. The whole plastic bag making machine uses microcomputer control, material-pufling by steppingmotor (which can be equipped with servomotor control system), and accuratesealing and cutting size.

4. It offers automatic counting and set table counting alarm and whole copyoutput system.

5. The imported variable frequency motor makes the equipment stable and saveson electricity.

6. The plastic bag making machine has a centralized oilsupply system.

TechnicalSpecifications of the Plastic Bag Making Machine, FQ-B

| Bag Making Width | 600mm |

| Bag Making Speed | 30-150pcs/min |

| Electric Heat Power | 380V. 50Hz. 2.0kw |

| Power of Main Motor | 1.1kw |

| Film Thickness | 0.01-0.05mm |

| Overall Dimensions (LxWxH ) | 3500×1160×1400mm |

As a major plastic bag making machine manufacturer based in China, ourcompany also supplies paper food bag making machine, paper cup forming machine,speed gravure printing machine, paper slitting machine, and much more.

Links:https://www.globefindpro.com/products/92958.html

-

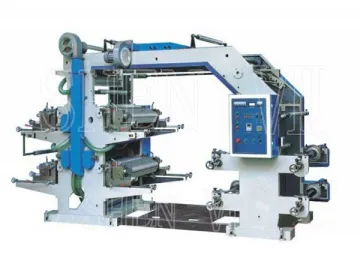

4 Color Flexographic Printing Machine

4 Color Flexographic Printing Machine

-

Non Woven Bag Handle Sealing Machine

Non Woven Bag Handle Sealing Machine

-

304 Threaded Steel Tube

304 Threaded Steel Tube

-

Stainless Steel Sheet

Stainless Steel Sheet

-

Plastic Bag Making Machine, SD-A

Plastic Bag Making Machine, SD-A

-

201 Threaded Stainless Steel Tube

201 Threaded Stainless Steel Tube

-

Non Woven Bag Making Machine

Non Woven Bag Making Machine

-

Co-Extrusion Film Blowing Machine

Co-Extrusion Film Blowing Machine

-

Paper Cutting Machine

Paper Cutting Machine

-

Non Woven Fabric Production Line

Non Woven Fabric Production Line

-

6 Color Flexographic Printing Machine

6 Color Flexographic Printing Machine

-

PE Film Blowing Machine

PE Film Blowing Machine